0.8 m³/h Capacity Veneer Dryer

Shine veneer dryer has the features of high productivity & energy efficiency with the lowest drying cost and perfect drying effect. Shine’s one deck 28m roller venner dryer has capacity at about 0.8m³/h -1m³/h, it's more suitable for small scaled production.

- Veneer thickness: 0.6-8mm

- Drying capacity (m³/day): About 22-24m³/day

- Electricity consumption: About 60kwh/hour

Product Description of 0.8 m³/h Capacity Veneer Dryer

0.8 m³/h Capacity Veneer Dryer uses the latest international veneer drying technology,which has the advantages of simple operation,safe and practical, stable operation,easy maintenance and so on. Shine’s veneer dryer can work on 24 hours a day, only 4-5 labors are needed, with manual veneer feeding and veneer collecting. (automation level can be upgraded)

one deck 0.8 m³/h Capacity Veneer Dryer

Veneer Dryer in Brazil Customer Factory

Product Parameter of 0.8 m³/h Capacity Veneer Dryer

Model No | GTH30-28 |

Working Width | 3m |

Deck | 1 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 24m |

Cooling area length | 4m |

Veneer thickness | 1.7 |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | About 22-27m³/day |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:7.5KW(6pc) |

Traction motor | Power: 5.5KW,frequency control(1pc) |

Cold air blower | Power:7.5KW(1pc) |

Air intake fan | Power: 11KW(1pc) |

2ton biomass burner | Power: 15KW |

Total power | 84KW

|

Actual electricity consumption | About 60kwh per hour |

Space covered about | 32m× 9m×2m |

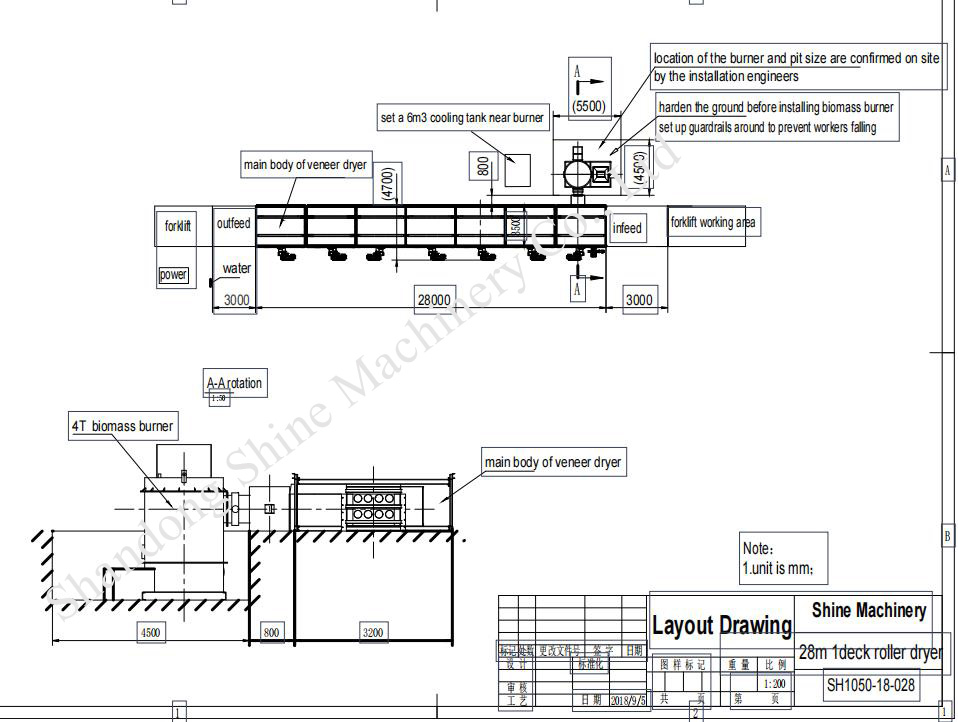

Layout Drawing of 0.8 m³/h Capacity Veneer Dryer

Shine's dryer uses direct heating of air, which greatly improves the efficiency of thermal energy utilization. During the drying process, thermal energy can be maximally utilized to reduce unnecessary energy loss, ensuring excellent drying results while lowering the energy consumption cost of the enterprise

The Installation

Shine one deck 28m veneer dryer was successfully installed in 2019 in Brazil.

We sincerely welcome all customers who are interested in investing in the single board industry to visit our factory for on-site inspection!

Here, you can witness the entire production process of Shenghuai veneer dryer with your own eyes - from the processing and assembly of precision components to the strict debugging and testing before the equipment leaves the factory, every link embodies our ultimate pursuit of quality.

Customer Case

From plywood factories in Romania to wooden doors production lines in Brazil, each case is accompanied by detailed production data and customer feedback. Our sales team will analyze how different configurations of equipment can match production capacity requirements based on your investment scale and target market, and even estimate the investment return cycle and profit margin based on your planning.

Our Factory

Established in 1999, Shandong Shine Machinery Co. Ltd is a large-scale enterprise specializing in R&D and production of veneer dryer and other plywood making machines. We are honored to be recognized as the vice chairman unit of Shandong Timber and Wood Products Distribution Association.

Transportation

We can customize the shipping method according to your needs. The container loading and shipping of veneer dryers is a crucial step in ensuring the safe delivery of equipment to customers. We always control every detail with a professional and rigorous attitude, providing reliable logistics support for global customers.