40 m Roller Veneer Dryer

Shine Machinery 40m Roller Veneer Dryer:

Efficient, Cost-Saving Solution for High-Quality Wood Veneer Drying

If you’re looking for a reliable, efficient way to dry wood veneers for plywood, furniture, or construction materials, Shine’s 40m roller veneer dryer (a top-tier wood veneer dryer) is the answer. Designed with modern plywood woodworking needs in mind, this machine combines high efficiency, low energy use, and smart customization to deliver exceptional results—all while keeping your operational costs in check.

Unbeatable Cost Efficiency: Low Fuel, Lower Bills

Shine’s 40m roller veneer dryer stands out for its low fuel consumption and energy-saving design. Unlike traditional dryers that rely on expensive thermal oil, steam, or electricity, this machine uses a more affordable fuel source—often waste wood from peeling or tree bark. This smart choice slashes your fuel costs drastically. In fact, the composite operating cost (labor + fuel + electricity) is just around $10 per cubic meter, making it one of the most budget-friendly options on the market.

2 deck 40 m Roller Veneer Dryer in Thailand

Roller Veneer Dryer in Zimbabwe Customer's Factory

Consistent, High-Quality Drying Results

What really sets Shine dryer apart is its ability to produce uniform, defect-free veneers. Here’s how:

Smooth, flat surfaces: The high-temperature drum comes into direct contact with wet veneers, ensuring even heat transfer. This eliminates wrinkles, end waviness, or cracks—common issues with less precise dryers.

Optimal moisture control: Every veneer exits with consistent moisture content, ready for gluing or laminating without warping or delamination.

Reduced heat loss: Advanced insulation and a closed-loop system minimize energy waste, so more heat goes into drying—not escaping.

The installation Process

Compact & Easy to Install: Save Space, Save Time

Space is often a challenge in workshops, but Shine’s 40m roller veneer dryer solves that. Its compact design requires minimal floor space, and it comes with fewer auxiliary components (no bulky extra parts). This means:

Quick transportation: No need for heavy machinery or complicated logistics.

Easy installation: Set up in hours, not days—so you can start production faster.

Video

Indonesia customer 2 deck veneer dryer

Product Parameters of 40 m Roller Veneer Dryer

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:11KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 11KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 163.5KW |

Actual electricity consumption | About 110kwh per hour |

Project Case and Customer Visiting

Every woodworking business has unique needs, and Shine’s dryer is built to match. We offer standardized production models that can be tailored to different capacities. Whether you need a single-section dryer for small workshops or a multi-section model for large factories, we’ll design it to fit your space, budget, and output goals.

Our Certificate - CE/ ISO(National Standard)

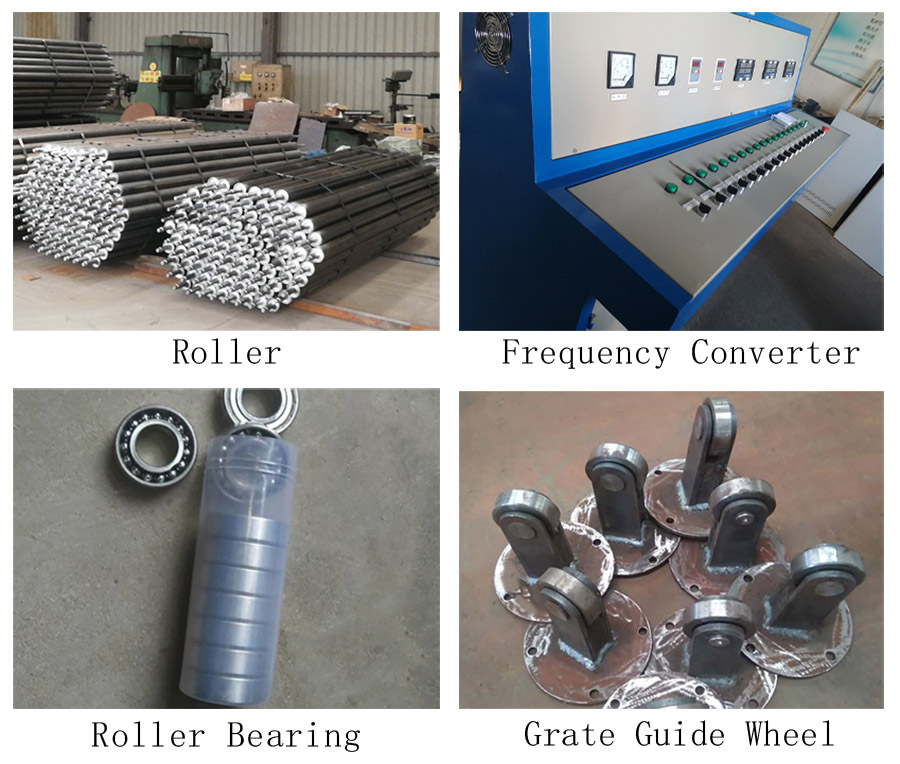

Parts of 40 m Roller Veneer Dryer

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment

7.Provide technical exchanging

8.Door to door service is possible

Product Packaging

Shine isn’t just a machinery supplier—we’re your partner in success. Our 40m roller veneer dryer is backed by years of R&D, rigorous quality testing, and a team of experts ready to support you. From installation to maintenance, we’re here to ensure your dryer runs smoothly, delivering high-quality veneers that boost your product value and keep your customers happy.

Veneer Dryer Humidity Removal System