Core Roller Veneer Dryer machine

Why You Need a Veneer Dryer (and Why Shine Stands Out)

Freshly cut veneers are like sponges—they hold onto moisture that can warp edges, create bubbles, or weaken glue joints if not dried properly. Traditional methods like sun-drying are slow, unreliable, and at the mercy of weather. That’s where Shine’s veneer dryer machine comes in: it’s fast, consistent, and tailored to your needs. Whether you’re working with thin decorative sheets (0.6mm) or thick industrial planks (8mm), this machine delivers predictable results every time.

Shine’s veneer dryer isn’t just a “box that heats things up”—it’s engineered with precision. Here’s what makes it tick:

1. Variable Speed Control: Adapt to Your Veneers

Thanks to its frequency conversion speed regulation system, the dryer automatically adjusts the feeding speed based on your veneer’s thickness and moisture content. Thick planks? The belt slows down to let heat penetrate evenly. Thin sheets? It speeds up to prevent over-drying. No more guessing games—just perfect drying, every batch.

2. Robust Design: Built to Last

The secret to Shine’s durability? Thick-walled rollers (engineered to resist distortion even under high heat). These rollers glide smoothly over veneers, ensuring flat, crack-free surfaces while minimizing wear and tear. The result? A machine that lasts years longer than cheaper models, with less downtime for repairs.

Key Advantages That Set Shine Apart

Energy Efficiency: Our well-developed heat exchange system recovers residual heat, slashing energy waste by up to 35%. No more sky-high utility bills—just efficient drying that saves you money.

Precise Moisture Control: The automatic temperature and speed control panel lets you dial in the exact moisture content your glue needs (no more “close enough”). This precision eliminates weak bonds and rework, boosting your first-pass yield.

High-Speed Drying: With a burner temperature 40–60°C hotter than traditional models (steam/thermal oil), Shine’s dryer reaches 140–180°C quickly. Drying cycles are shorter, output is higher, and your workshop stays on schedule.

Flawless Results: After drying, veneers are smooth, flat, and free of cracks, wrinkles, or end ripples. No more “buckling” (upward curl) or “waviness” (side-to-side rippling)—just pristine sheets ready for your next step.

Minimal Shrinkage & Hardening: Unlike cheaper dryers that cause veneers to harden or shrink unevenly, Shine’s design keeps shrinkage and hardening to a minimum. No collapsed sheets or honeycomb structures—just stable, reliable veneers.

Built for Your Business: Custom Solutions & Support

No two woodworking shops are the same, and Shine’s dryer is built to prove it. We offer:

Custom Models: Our R&D team works with you to design dryers that fit your space, budget, and production goals—whether you need a compact unit for small batches or a multi-section system for large factories.

24/7 Support: Forgot how to adjust the speed? Need help troubleshooting? Our team is here around the clock—online, on-site, or over the phone—to keep your dryer running smoothly.

Product Parameters of Veneer Dryer

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 108.5KW |

Actual electricity consumption | About 76kwh per hour |

Customer Products

Customer-First Mindset: We listen to your needs, adapt our solutions, and stand by our products—because your success is our success.

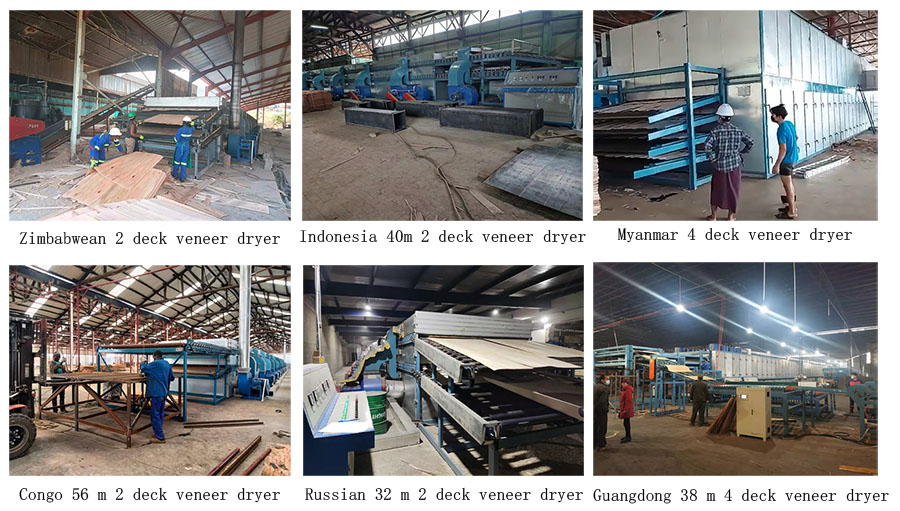

Customer Case

Shine Factory

Quality focus: Every machine undergoes rigorous testing to ensure it meets international standards—so you can trust it to deliver consistent results.

Decades of experience: We’ve spent years refining our designs to balance efficiency, durability, and cost-effectiveness.

Packaging & Shipping

Shipping to West Africa, a 2 deck 48m roller veneer dryer with Biomass Burner.