Automated Conveyor Veneer Dryer

Shine Machinery Wood Veneer Dryer: Customized Excellence for Efficient, Cost-Effective Veneer Production

In the competitive woodworking industry, consistency, reliability, and cost efficiency are non-negotiable. Shine Machinery’s wood veneer dryer redefines industry standards with its tailored solutions, robust engineering, and proven performance—designed to elevate your veneer production from ordinary to exceptional.

1.Customizable (customized one-stop service)

2. Professional factory production

3.Stable equipment and low failure rate

4. Low comprehensive operating cost, the cost of one cubic board is 6-12$/m3

Automated Conveyor Veneer Dryer

In the dynamic world of plywood manufacturing, optimizing drying processes is critical to maintaining quality, reducing costs, and boosting productivity. Shine Machinery’s automated conveyor veneer Dryer emerges as a game-changer for medium and small-scale plywood plants, combining energy efficiency, versatility, and robust engineering to deliver unmatched drying performance.

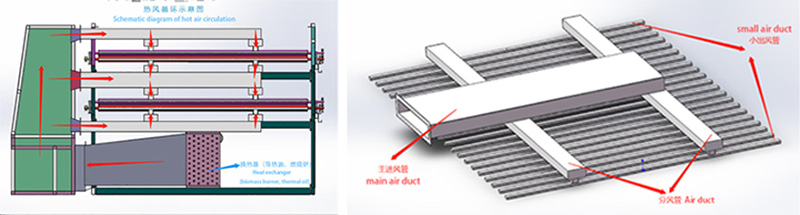

Low Power Consumption, High Adaptability

Designed for small and medium plywood plants, this 4-deck roller veneer dryer operates with low power consumption, making it a cost-effective choice for facilities with budget constraints or limited energy access. Its compact yet powerful design ensures reliable operation across varying production scales, from processing thin decorative veneers to thick industrial planks.

Automatic Feeding System: Save Labor, Boost Efficiency

A standout feature is its automatic feeding device, which eliminates manual handling of veneers. This system streamlines the loading process, reducing labor costs by up to 30% and minimizing material waste. Whether you’re drying core veneers for structural plywood or decorative sheets for furniture, the machine ensures continuous, uninterrupted workflow.

High-Temperature Drying: Perfect Moisture Control

The 4-deck design ensures uniform heat distribution across all drying layers, with internal temperatures reaching levels high enough to rapidly reduce moisture content. This precision drying guarantees that veneers exit the machine with:

Uniform moisture content (0–12% industry standard).

Flat, wrinkle-free surfaces—no buckling, end waviness, or surface defects.

Optimal bonding readiness: Pristine surface conditions ideal for gluing, laminating, or coating.

Durable Design: Low Maintenance, Long Lifespan

Built for industrial rigor, the dryer features:

φ102 steel rollers: Robust and corrosion-resistant, ensuring long-term durability even under heavy daily use.

High-temperature bearings: Engineered to withstand extreme conditions (-20°C to 500°C), eliminating the need for frequent oil injection and simplifying daily maintenance.

Product Parameters of Conveyor Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

The installation

In Brasov, Romania (4 decks 40m roller dryer)

In South Africa (4 decks 50m roller dryer)

Customer Case

Welcome investors to visit our customer case site nearby. You can have in-depth communication with local customers to understand their real experiences in the use of equipment, including details such as daily operation, maintenance, and production efficiency.