Roller Drying Machine for Veneer

Type: Veneer Roller Dryer

Working width: 3 m

Veneer thickness: 0.8-8 mm

Heating zone length: 32 m.

Drying capacity (m³/day): ·110-120

Water humidity in veneer: Fresh veneer up to approximately 0-15%.

Cost: 6-12$/m3 (labor+fuel+electricity)

Heat source: biomass burner (other options available)

Veneer roller dryer plant

Shine veneer drum dryer features high productivity, high energy efficiency, low drying cost and good drying effect. The productivity of this four-layer 36-meter veneer dryer can reach 4.6-5 m³ per hour. Comprehensively The cost is only 6-12 USD/m3. It can be dried to 0.8-8mm, and the minimum can be dried to 0%.

If you want to know more detailed information about the machine (performance, detailed parameters, videos, etc.), please contact us!

The veneer dryer consists of an inlet, a drying area, a cooling area and an outlet. The dryer size can be customized according to production capacity, process and space. (Both front and rear veneer feed as well as receiving veneer can be customized according to customer's needs)

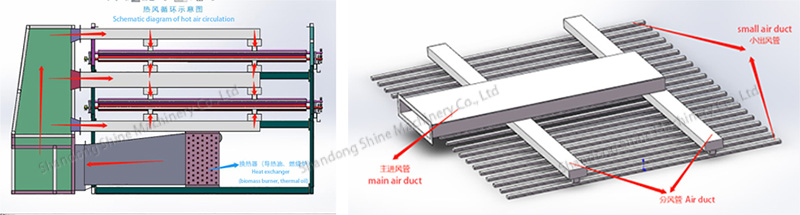

Heat exchange system and hot air circulation system

In the Shine heat exchanger, heat transfer occurs in stages, the characteristics of each section of the heat exchanger are different, and the hot air exchanges heat through the heat exchanger and distributes it evenly across the veneer. After drying, the veneer has uniform moisture content, smooth, without warping or waviness at the ends; no chips, surface in good condition for gluing.

Automatic electrical control and frequency conversion system

The veneer dryer uses automatic electric control and frequency conversion system, which can automatically adjust the transmission speed and temperature according to the veneer thickness and moisture content to achieve the perfect drying effect.

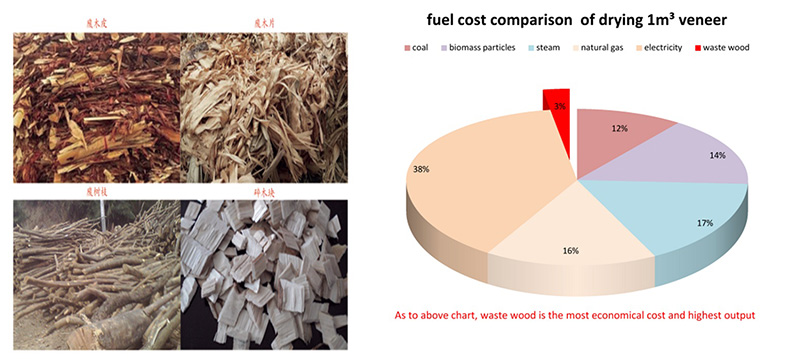

Veneer Dryer Heat Source

Patented biomass burner

The biomass burner is a patented Shine product. It can burn all kinds of wood waste directly, which mainly reduces drying costs. Compared with veneer dryer with steam or heat transfer oil, the drying cost is greatly reduced.

Thermal oil

Thermal oil veneer dryer uses heat-conducting oil as the heat transfer medium to supply heat, with fast temperature rise speed, short humidity adjustment time, large circulating air flow, uniform drying, small humidity error and large output. Shine Heat thermal oil veneer dryer can achieve automatic temperature control, humidity control and automatic wind direction change, which can meet the drying requirements of various wood species.

Couple

In a steam dryer, the drying agent is heated by steam from the combustion of various types of fuel. In steam dryers, veneer dries under milder conditions than in gas dryers. The typical drying temperature inside steam dryers is around 160℃.

Natural gas

Natural gas heated veneer dryers are one of the traditional types of veneer dryers. The drying temperature is higher, which significantly reduces the drying time for veneer. It's clean energy, which means no air pollution problems. Can perform high-precision drying temperature control.

Dryer Product Parameters for veneer

Model No. |

GTH30-36 |

Working width |

3 m |

Number of floors |

4 |

Heating zone length |

32 m |

Cooling zone length |

4 m |

Veneer thickness |

0.6-8 mm |

Final humidity (%) |

Fresh veneer up to approximately 10% |

Heating material and drying temperature |

Wood waste, 140-200 °C adjustable. There is an automatic temperature control and speed control system, which can guarantee stable moisture content. |

Drying capacity (m³/h) |

5 kbm |

Speed submissions |

5-22 m/min, chain 16A |

Into the fan hot air |

Power: 8 kW (16pcs) |

Traction motor |

Power: 5.5 kW, frequency control (4pcs) |

Into the fan cold air |

Power: 4 kW (4pcs) |

Air intake fan |

Power: 15 kW (2pcs) |

10 Ton Biomass Burner |

Power: 16.5 kW |

general power |

212.5 kW |

Actual electricity consumption |

About 170 kWh per hour |

Main frame material |

international rectangular tube (50*100); square tube (50*50) |

Side insulation board |

galvanized steel sheet filled with aluminum silicate blanket |

Upper insulation board |

rock wool composite board |

Air spray pipe |

international galvanized rectangular pipe |

Reducer (including motor) |

power 7.5kw motor speed 1500r/min |

Our certificates

Customer and factory visit

Our services

Pre-sales services:

1) Provide free consultation to all plywood dryers.

2) According to customers' special requirements, we offer reasonable plans and free designs to help you select equipment.

3) Welcome to our factory

Services during sales:

1) Inspect the machine before leaving the factory.

2) Installation and debugging of equipment abroad.

3) Train the first line operator.

After-sales service:

1) 24 hours online service

2) Provide a VIDEO showing the installation and debugging of the equipment.

3) Provide technical exchange (Technical phone: +8615665878109) Door to door service is possible.

Packaging and delivery