Shine Veneer Dryer Machine

Type: Roller Veneer Dryer – Engineered for smooth, consistent veneer and optimal heat distribution.

Working Width: 3m – Accommodates customized wood veneer for enhanced productivity.

Veneer Thickness Range: 0.6-8mm – Suitable for decorative veneers to thick plywood cores.

Heating Area Length: 34m – Extended drying zone ensures thorough moisture removal.

Drying Capacity: ~120m³ per day – High-output performance for continuous production.

Final Moisture Content: Down to 10% – Achieves industry-standard dryness for superior veneer quality.

Operating Cost: Only 6-12$/m³ (including labor, fuel & electricity) – One of the most cost-effective Veneer Dryers for Sale on the market.

Heat Source: Standard biomass burner (eco-friendly & cost-efficient), with optional gas, steam, or electric heating for flexibility.

Shine Veneer Dryer Machine

Shine biomass veneer dryer machine is widely valued for the lowest operation cost, high drying capacity, and energy efficiency as well as high-quality veneer output. It is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad. The composite drying cost of a high-efficiency veneer dryer is about USD 10/m3 including the labor cost, fuel cost, and electricity power.

Sealing thermal insulation system

In order to achieve best drying efficiency of the ejector roller veneer dryer machine, the shell of the machine is insulated by the shell with a thickness of 75MM-100MM, so as to prevent heat loss in the machine and no loss of air volume. Thus, to achieve the most ideal sealing and insulation effect.

Dehumidifying system

The dehumidifying system of the shine veneer dryer machine is operated by several dehumidifying holes located in the machine, through the adjustment of the valve, and adopts the function of the automatic damp removing system or the mechanical strong dehumidifying system to achieve the best effect of humidity discharge.

Technical Parameters of Veneer Dryer Machine

Model No | GTH30-38 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 34m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(34pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

10-ton biomass burner | Power: 16.5KW |

Total power | 228.5KW |

Actual electricity consumption | About 160kWh per hour |

Shine Certificate

Shinei Machinery specializes in building high-efficiency Veneer Dryer Machine, which has passed CE certification and meets the strict safety and environmental protection standards of the European Union! Our equipment adopts advanced drying technology to ensure energy saving, stability, and high efficiency, which is your reliable industrial drying solution.

Shine Factory

As an industry-leading veneer dryer manufacturer, Shine Machinery has 20 years + professional production experience and is committed to providing customers with efficient and reliable drying solutions. We integrate R&D, production, and sales into one, and build each high-efficiency veneer dryer with exquisite craftsmanship to ensure excellent performance and durability of the equipment.

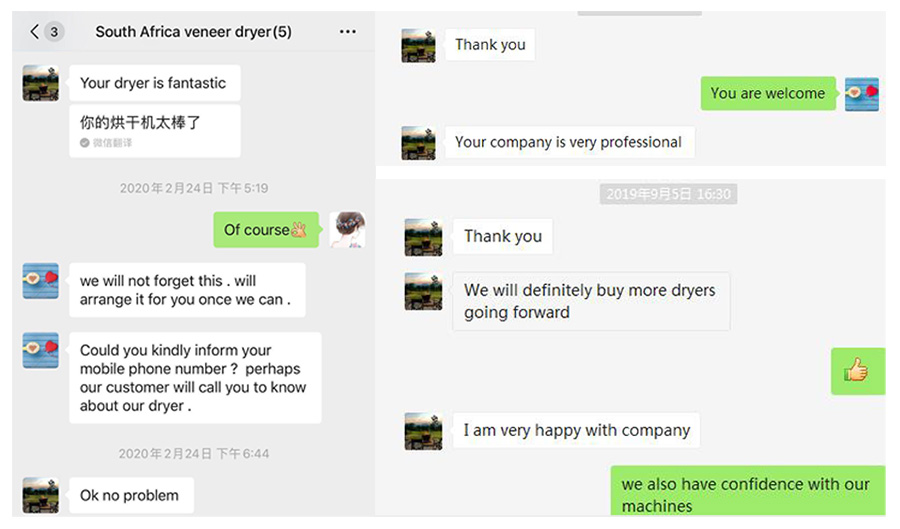

The customer evaluation

Recently, James, the head of a wood processing company in Johannesburg, South Africa, sent us enthusiastic feedback. After using Shine's high efficiency Veneer Dryer Machine for three months, he excitedly said, “This is the most reliable drying equipment we have ever used!”

Our Services

Pre-sale services:

1) Provide a free consultation on all Core Veneer Dryer Machines.

2) According to the clients' special requirement, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment.

3) Train the first-line operator.

After-sales services:

1) 24 hours online service(WhatsApp:+8615806625431)

2) Provide the VIDEO with Install and debugging the equipment.

3) Provide technical exchanging(Technical phone:15665878109)Door to door service is possible.

Packaging & Shipping

At Shine Machinery, we ensure every veneer dryer machine is securely packaged and efficiently shipped to guarantee safe arrival at your facility.