veneer dryer manufacturer

It adopts a newly upgraded technology. The hot air blower and the cold air blower use the latest axial flow fan.

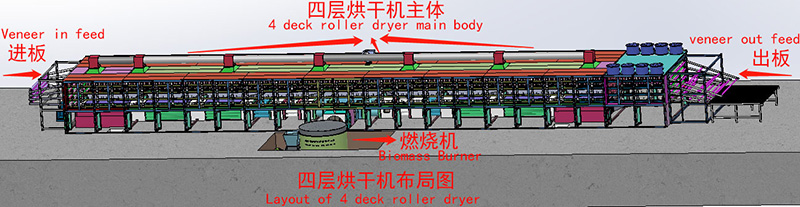

As a premier manufacturer of Wood Veneer Dryer and Veneer Continuous Dryer systems, we proudly offer our high-performance Roller Veneer Dryer with 3m working width and 32m heating area, processing veneer thickness from 0.8-8mm to perfection (0-15% moisture content). Our advanced technology reduces total power consumption by 35% compared to conventional dryers, achieving remarkable energy savings with operating costs as low as 6-12$/m³ (labor+fuel+electricity included).

Veneer Dryer Manufacturer

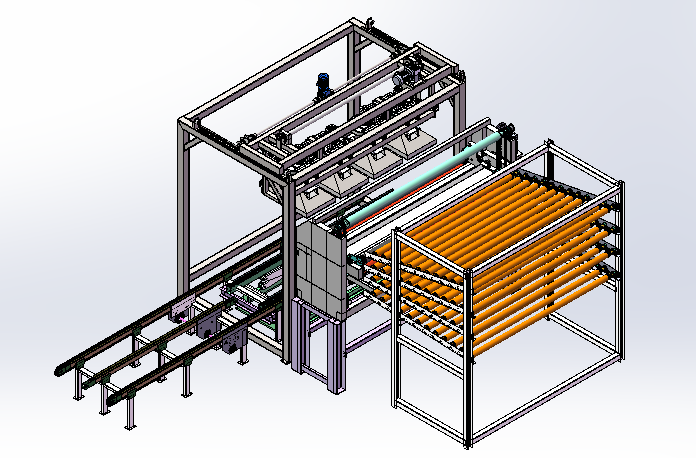

Shine machinery 4 deck roller veneer dryer adopts axial flow fan. It reduces the power of the whole machine by 38%. It is equipped with full automatic control and frequency conversion control system, which can automatically adjust the transmission speed and temperature according to different veneer thickness and moisture content to achieve the ideal drying effect. Shine always aims to meet the needs of customers and provide you with customized veneer drying solutions.

Advantages of Veneer Dryer Machine

The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content.

After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

Deformity is kept to a minimum, and veneer collapse and honeycomb structure are avoided.

We have a professional R&D team which can design different models according to customers’ special requirements.

Product Parameters of Veneer Drying

Model No | GTH30-36 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 32m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 110 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(32pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 212.5KW |

Actual electricity consumption | About 149kwh per hour |

Customer Case

As an industry-leading veneer dryer manufacturer, Shine Machinery's equipment has been successfully used at customer sites in 30+ countries around the world, from the tropical rainforests of Southeast Asia to the arid zones of Africa, where our Wood Veneer Dryer and Veneer Continuous Dryer have demonstrated excellent adaptability and stability.

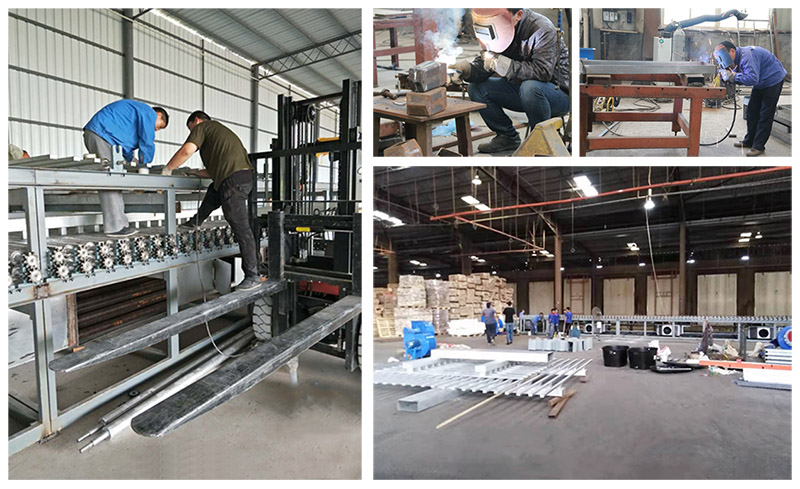

The Factory

As a veneer dryer manufacturer with 20 years of professional experience, Shine Machinery has provided customized drying solutions to customers in 50+ countries worldwide. We understand different wood characteristics and production needs, and we can create a Wood Veneer Dryer and Veneer Continuous Dryer system for each customer.

The installation

Shine Machinery provides customers with full technical support for installation and commissioning services to ensure that each veneer dryer runs efficiently and stably. The debugging process is equally rigorous, requiring calibration and adjustment of key parameters, including temperature gradient, airflow rate, conveyor belt speed, and humidity control, to match each customer's specific wood species, veneer thickness, and yield.