20m Automatic Veneer Dryer Machine

Shine 20m automatic veneer dryer machine is our high-end veneer drying machine with the salient features of a bigger drying output. Maximum veneer drying capacity can reach around 200m3. The rollers use φ102 seamless steel pipe. The bearings of the 4-deck 20m automatic veneer dryer machine featured high-temperature resistance of 500 degrees Celsius and low-temperature resistance of -20 degrees Celsius. which has no need to inject oil and easy maintenance in the daily operation.

Shine 20m Automatic Veneer Dryer Machine – High-Efficiency Drying Solution

Shine Machinery's 20m automatic veneer dryer machine represents our premium-grade veneer drying equipment, engineered for maximum productivity and reliability. With an impressive drying capacity of up to 200m³ per day, this machine is ideal for large-scale plywood and veneer production plants.

4deck 20m automatic veneer dryer machine in Latvia

Veneer Dryer in Myanmar Customer's Factory

Biomass Burner Veneer Dryer machine

Veneer dryer chain, Roller running veneer, Outfeed

Key Features & Advantages

1. High-Capacity 4-Deck Automatic Feeder of Veneer Dryer

Efficient Multi-Layer Drying: The 4-deck automatic feeder of the veneer dryer ensures smooth and continuous veneer feeding, optimizing drying uniformity across all layers.

Seamless Steel Rollers (φ102mm): Heavy-duty construction for enhanced durability and stable operation under high-temperature conditions.

High/Low-Temperature Resistant Bearings: Specially designed bearings withstand extreme temperatures ranging from -20°C to 500°C, eliminating the need for frequent oil injection and reducing maintenance efforts.

2. Advanced Biomass Burner for Veneer Dryer

Eco-Friendly & Cost-Effective Heating: The integrated biomass burner for the veneer dryer supports sustainable fuel options (wood chips, pellets, etc.), reducing operational costs while maintaining high thermal efficiency.

Precise Temperature Control: Ensures stable heat distribution (140-200°C) for consistent drying results without overheating or energy waste.

3. Intelligent Automation & User-Friendly Design

PLC Control System: Automatically adjusts drying speed and temperature based on real-time moisture detection, ensuring optimal drying quality.

Low Maintenance & Long Service Life: Robust construction and high-quality materials minimize wear and tear, reducing downtime.

Video of the 20m Automatic Veneer Dryer Machine

Technical Parameters of 20m Automatic Veneer Dryer Machine

Model No | GTH30-20 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 16m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee that the moisture content is consistent. |

Drying capacity (m³/h) | 2.5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(16pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(1pc) |

6-ton biomass burner | Power: 16.5KW |

Total power | 145.5KW |

Actual electricity consumption | About 100kwh per hour |

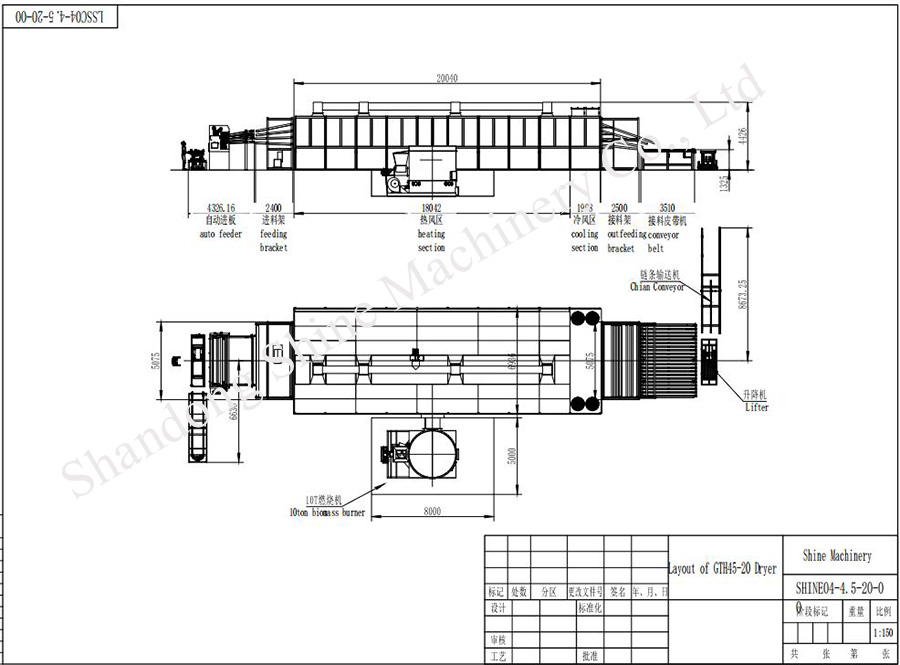

Layout Drawing of 20m Automatic Veneer Dryer Machine

Shine Machinery understands that different customers have different requirements for wood veneer drying processes. We provide comprehensive customized design services, from equipment parameters to production line layout, which can be adjusted according to your needs to ensure that the dryer perfectly matches your production requirements.

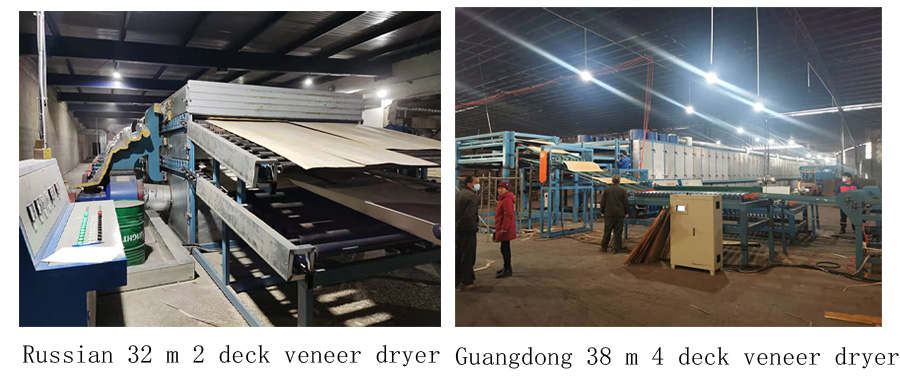

Project Case

Whether your factory is located in an extremely cold region with temperatures as low as -30°C or a hot and humid tropical region with temperatures above 40°C, Shine wood veneer dryers ensure stable output and excellent drying results through their intelligent temperature control system and modular design, meeting production needs in different climatic conditions around the world.

Parts of the Veneer Dryer

Shine Machinery has always adhered to the concept of “quality first, lean manufacturing”, ensuring that every component of each single-board dryer undergoes rigorous inspection and testing to achieve an ultra-long service life, providing customers with stable and reliable drying solutions.

Customer Visits

Shine Machinery, a leading enterprise in the single-board drying industry, welcomes numerous customers from Russia, Southeast Asia, South America, Africa, and other regions to visit and inspect its factory every year. Through on-site observation of equipment operation and first-hand experience of drying results, customers have highly praised the efficiency, stability, and intelligence level of Shine Machinery's wood veneer dryers!

Customers from all over the world visit

FAQ

1. How much does it cost to dry 1m³ of veneer?

About $12, including labor, fuel, and electricity, will fluctuate with local prices.

2. How to choose a product that is most suitable for me?

A: Our company has professional engineers to select the most suitable product according to your capacity and areas, saving your time and cost.

3. Will it be difficult to install?

A: We will send professional engineers to guide. In remote situations, engineers will video assist workers with installation. There are many remote success stories.

4. Can I see the real equipment and factory?

Yes. We can provide the location of our veneer dryers that have been put into production, and we can contact and communicate with the users for you. Hence, you can see the working conditions of our roller dryer machine.