Core Veneer Dryer Machine

Shine core veneer dryer machine adopts automatic electric control and frequency conversion system,which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.Equipped with automatic veneer feeder and automatic collection system,which not only improves the drying efficiency but also saves labor cost mostly.

Product Description of Core Veneer Dryer Machine

Core Veneer Dryer Machine is widely used in flatting drying of plywood.plywood veneer dryer machine is used to dry the wood core veneer.Usually the veneer is peeled from fresh logs and has a very high moisture even can not be directly used.The core veneer dryer machine is the most efficient drying methods,which can dry rubber wood,eucalyptus,birch,teak etc all kinds of hard wood and soft wood veneer.

The veneer after drying is flat and smooth,the moisture can be dried to 0.It is continous feeding and drying so the efficient is very high.Good drying effect and easy operation make plywood veneer dryer machine to be best choice for plywood making.

4 Deck Core Veneer Dryer Machine in Latvia

Core Veneer Dryer Machine

Features:

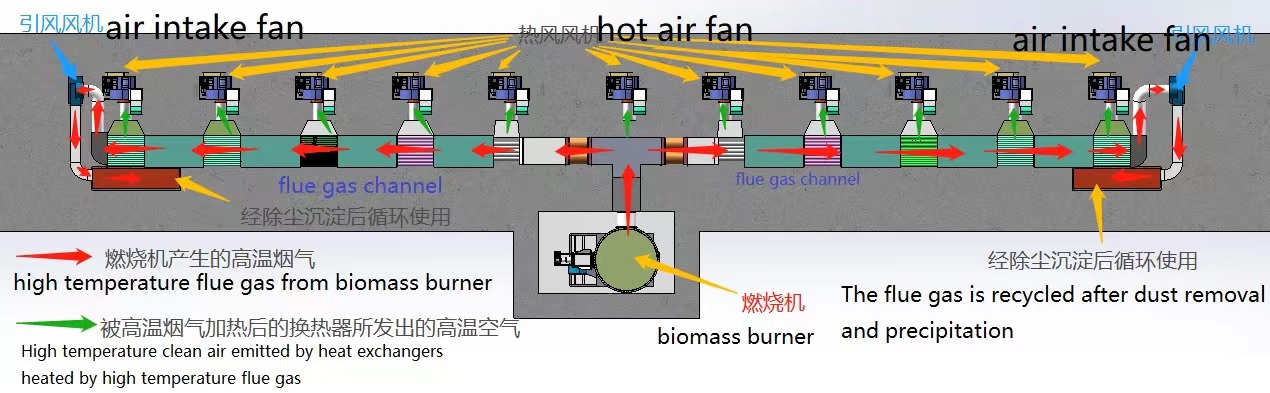

1. This model is a straight-through horizontal circulation core veneer dryer machine. Its thermal cycle design draws on the advantages of advanced European dryer technology, and adopts an upright centrifugal fan with a volute (flow rate of 45,000 to 62,000 m3/ h).

2. The new type of heat exchanger and the rectangular variable-section spray box make the high-speed jet airflow acting on the surface of the veneer uniform. The hot air blowers in the heating chambers in the front and rear areas are arranged separately from left to right, so as to ensure that the dried veneer obtains a consistent final moisture content at each point.

3.In order to adapt to the humid tropical climate, the length of the cooling open section is appropriately lengthened to facilitate the cooling of the dried veneer and reduce the phenomenon of damp return.

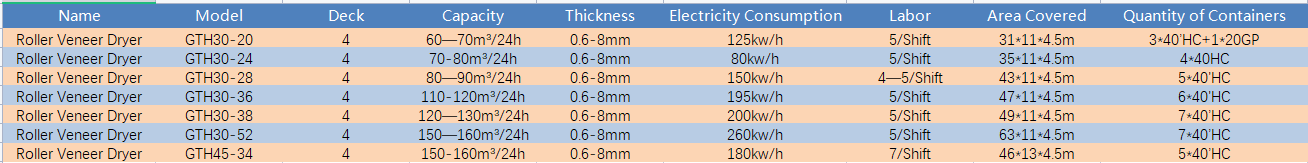

Product Parameters of Core Veneer Dryer Machine

Customer Case

Our Certificate

Product Packaging

FAQ

Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machines by ourselves.

Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paid against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 50 countries customer.