veneered panel dryer

The electricity consumption of the shine veneer dryer has been reduced by 35%, and you can visit the case site nearby.

Type: Biomass Veneer Dryer

Working Width: 3m

Veneer thickness: 0.8-8mm

Heating Area Length: 48m

Drying capacity (m³/day) : 150-160

Heat Source: Biomass Burner (Other options available)

24 hours online service(WhatsApp:15806625431)

Veneered Panel Dryer

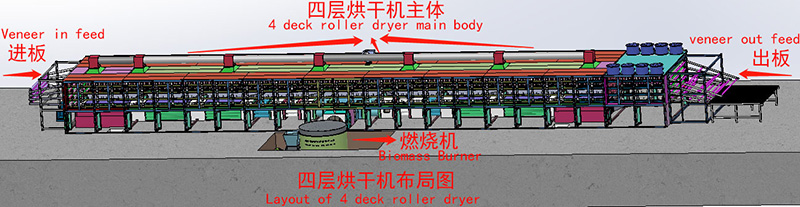

4 deck veneer dryer equipped with automatic feeder device can feed the veneer to dryer and save labor cost mostly. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness. Less maintenance is required for Shine veneer dryer machine and no veneer jamming leading to less downtime. Shine biomass veneer dryers machine can reach user's special requirements and achieve ideal drying effect mostly.

Advantages Of Veneered Panel Dryer

1. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

2. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

3. The Shine veneer dryer directly heats the air, which has a higher temperature than traditional heat sources, and can be stably controlled at 140-180 ℃, maintaining a stable temperature gradient throughout the process to avoid changes in wood properties caused by local overheating.

4. The veneer processed by the Shine's dryer presents a remarkable high-quality state: the surface is as smooth as a mirror, completely avoiding the cracks, wrinkles, and end ripples commonly seen in traditional drying.

5. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

6. We have a professional R&D team which can design different models according to customer’s special requirement.

7. The perfect after-sale service team can supply 24 hours online service.

Product Parameters Of Veneered Panel Dryer

Model No | GTH30-52 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 48m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 6.3-6.7 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(48pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 284.5KW |

Actual electricity consumption | About 200kwh per hour |

Overall Dimension(L*W*H) | 63m×11m×3.5m |

Customer Case Site

Shine Machinery has over a hundred customer case sites worldwide. With the stable performance and uniform drying effect of Shine dryers, its exported veneers have significantly enhanced their competitiveness in the international market, and the export volume has been increasing year by year.We can collaborate with nearby customer factories for you, allowing you to witness the operation status of equipment in high-end decorative panels, small batch production, and other scenarios firsthand.

The Factory

Shandong Shine Machinery Co.,Ltd has been engaged in the production of dryer equipment for over 20 years. The industry accumulation over these 20 years is not only a measure of time, but also an accumulation of technical strength and production experience. The company has a professional R&D team and production department. They always keep up with the technological trends in the global wood processing industry, conducting in-depth research on the characteristics of different woods, drying processes, and the demand for equipment based on the climate characteristics of different countries.

Packaging & Shipping

Every time a dryer is sent out, it means that a new veneer factory will be put into production. Shipping is not the focus of our cooperation. After the equipment arrives at the port, we will arrange professional technicians to help customers install and guide the use of the dryer on site, and do a good job in maintaining the equipment in the later stage, increasing production capacity for more manufacturers.