Rapid Veneer Dryer for Quick and Reliable Drying Solutions

Our professional factory specializes in producing highly automated and efficient wood drying equipment, including a customizable rapid veneer dryer that offers tailored one-stop services. The dryer features a φ89mm special shaft tube for the rollers, ensuring excellent corrosion and rust resistance. With a fully automatic veneer feeding and receiving system, it significantly improves operational efficiency. The main electrical components use renowned domestic and international brands for enhanced reliability. Moreover, the equipment is energy-saving and power-efficient, utilizing axial flow fans to reduce the total power consumption of the whole machine by 38%.

Shine veneer drying provides you with a one-stop solution. The dried veneer has uniform moisture content, is flat, has no wrinkles or end ripples, no cracks, and has a good surface glued state. The power of the whole machine is reduced by 38%, and the power consumption is greatly reduced compared with the traditional veneer dryer.

Advantages of Veneer Dryer Machine

1. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

2. The control cabinet has an automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

3. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

4. After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

5. Shrinkage and hardening are kept to a minimum, and veneer collapse and honeycomb structure are avoided.

6. We have a professional R&D team that can design different models according to the customer’s special requirements.

7. The perfect after-sales service team can supply 24-hour online service.

Product Parameters of Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1-deck veneer dryer | 2-deck veneer dryer | 4-deck veneer dryer | 6-deck veneer dryer | |||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Customer Case

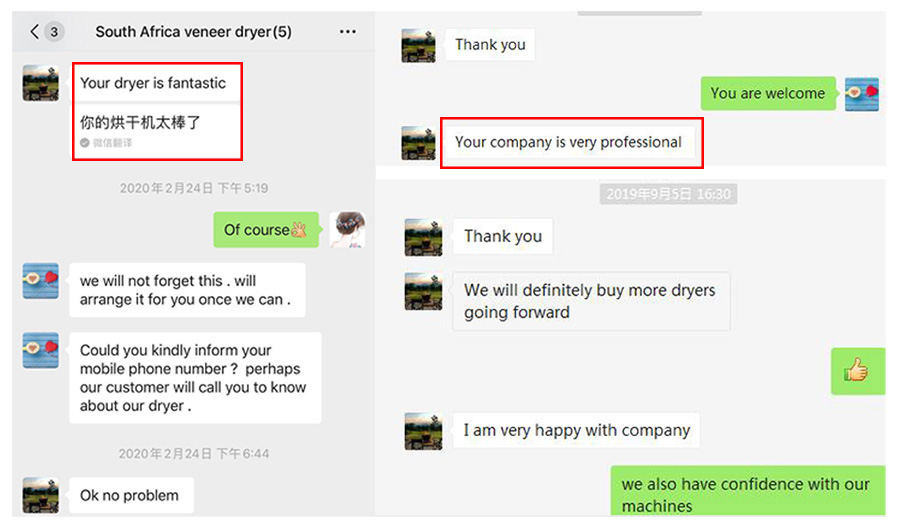

Our success stories span numerous timber processing hubs across the nation and overseas. From large forestry conglomerates to specialized manufacturers practicing lean production, countless clients operate Shine veneer dryers around the clock at their sites, witnessing the exceptional stability and remarkable benefits delivered by our equipment. This extensive customer base stands as the most compelling testament to our product quality and reputation.

The customer evaluation

“We chose Shine because of their professional pre-sales communication and strong technical support. The rapid veneer dryer has significantly increased our production efficiency. The fully automatic feeding system reduces our labor costs, and the drying quality is very uniform, which is crucial for our high-end veneer products. The engineer came to our factory for installation and stayed until our operators were fully confident. Great machine, great service!”

The Factory

Choosing drying equipment means choosing the manufacturing strength behind it. With its deep industry expertise, leading R&D and manufacturing capabilities, and comprehensive service offerings, Shine Woodworking Machinery has become a trusted partner for customers worldwide.

Packaging & Shipping

We understand that ensuring your equipment arrives safely and intact at your facility is just as important as the quality of the equipment itself. Shine Woodworking Machinery has established a standardized and meticulous packing and shipping system to guarantee a seamless journey from our factory to your installation site.