Biomass Burner Veneer Dryer

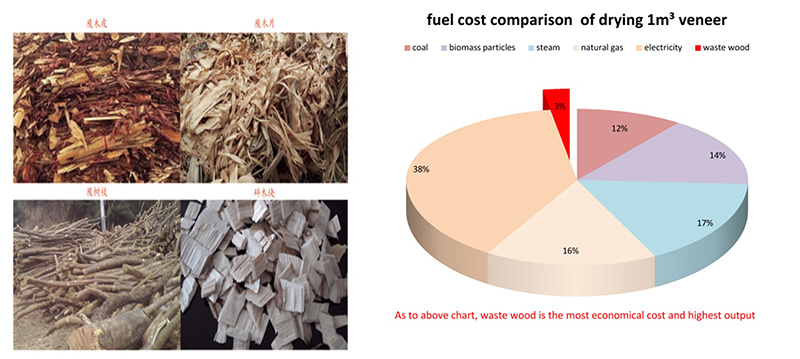

High-quality biomass burner veneer dryer, a patented veneer dryer independently developed by Shine Machinery, can directly use crushed wood waste, tree bark as fuel to provide hot air to the veneer dryer, which greatly reduces the drying cost and is energy-saving and environmentally friendly at the same time. No need to buy a steam boiler or thermal oil heater. The temperature in the burner is 40-60℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-200 ℃, which shortens the drying time and increases the output.

Biomass burner veneer dryer adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve an ideal drying effect. The veneer after drying in the Shine veneer dryer is smooth, and the moisture content is uniform. The high-temperature drum has direct contact with the wet veneer for heat transfer, the heat efficiency is high the heat loss is small, and the heat loss is reduced.

The biomass burner is one of the Shine patented products, which can burn all kinds of waste wood directly to reduce the drying cost mostly. The temperature in the biomass burner is up to 800 degrees Celsius and 140-180 degrees Celsius in the heating section of the dryer, which can be adjusted, and the temperature control accuracy is ±5℃. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. It is also environmentally friendly with no smoke and no dust, low energy consumption with high output and quality.

Product Parameter of Biomass Burner Veneer Dryer

Model No | GTH30-28 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 24m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 35-40cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(6pc) |

Traction motor | Power: 5.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 7.5KW(1pc) |

4-ton biomass burner | Power: 16.5KW |

Total power | 73.5KW |

Actual electricity consumption | About 52kwh per hour |

Covered Space of the whole machine | 34M X 9M X 3M |

Customer Case

Process Adaptation: Customized drying curves tailored to client raw material characteristics (wood species/thickness/initial moisture content)

Heat Source Configuration: Flexible adaptation to multiple heat source solutions, including steam, thermal oil, natural gas, and biomass

Automation Level: Offers configuration options ranging from basic versions to fully automated intelligent control systems

Site Optimization: Equipment layout and structural dimension optimization designed specifically for the client facility conditions

Factory

Choosing Shine means choosing a reliable guarantee built on large-scale manufacturing, cutting-edge craftsmanship, stringent quality control, and professional service. We cordially invite you to visit our factory, witness our capabilities firsthand, and explore collaboration opportunities together!

Our Services

Pre-sale services:

1) Provide a free consultation on all veneer production lines

2) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After-sales services:

1) 24-hour online service.

2) Provide the VIDEO on installing and debugging the equipment.

3) Provide technical exchanging(Technical phone:+8615806625431)Door to door service is possible.