The installation of the 2 deck veneer dryer purchased by another of our customers has been completed! This wood veneer dryer is equipped with our biomass burner, which saves fuel costs and uses new technology to save energy and electricity. Our engineers will go to the customer's factory to guide

2023/12/07 10:20

The second set of 4 deck veneer dryers ordered by our Latvian customer has been completed and is ready to be shipped. The customer was very satisfied with the first set after purchasing the first set. They expanded production this year and approached us to order another one. Thank you very much for

2023/12/05 10:23

The recent Russian Woodworking Exhibition is in progress. Our company's Russian agent participated in this exhibition. Our equipment has the advantages of high efficiency, energy saving and low drying cost. With our biomass burner, it can save fuel for you. It can directly burn various Plant waste

2023/11/30 11:17

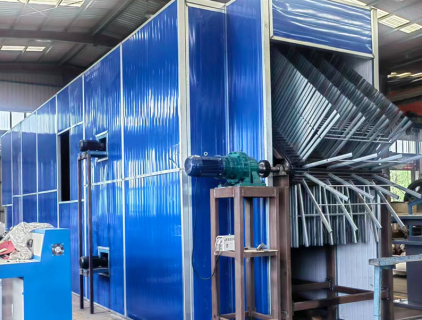

The 4 deck 50 m 4.5m wide veneer dryer purchased by our South African customer has been installed. Our technicians went to the customer's factory to guide the installation. The customer is very satisfied with the equipment and looks forward to the official test run!

2023/11/28 10:15

Shine veneer dryers are available with outputs ranging from a dozen cubic meters to more than a hundred cubic meters. They have their own heat source biomass burner; they can directly burn waste bark to save fuel costs (it can also be used with other heat sources). The newly upgraded dryer reduces

2023/11/23 10:01

Today, one of our Guangxi customers went to our Guangdong customer factory to visit the actual operation site of the veneer dryer. Our boss led the explanation. This veneer dryer is a four-layer 48-meter-long veneer dryer with a biomass burner. The customer Installing a water film dust removal

2023/11/16 09:23

The 2 deck veneer dryer ordered by our customer has been produced and is being shipped. Our engineers will go to the site to guide the installation. The engineer will return only after guiding the equipment to operate normally. If you want to see the site, you can contact us in advance. We went to

2023/11/14 09:47

The double-layer 30-meter-equipped 4-ton burner purchased by our customer in Zimbabwe has been installed and is currently in operation. The customer is using it to dry pine and eucalyptus wood with a thickness of 2.45mm. The feedback is that the effect is very good, and the production capacity will

2023/11/09 10:52

The GTH45-50 four-layer biomass roller dryer purchased by our South African customer is currently being installed. It is installed under the guidance of our technicians at the customer's factory. Using new technology, the power of the whole machine has been reduced by 38%, and the production

2023/11/09 09:34

Our veneer dryer purchased by a Romanian customer has recently been shipped to the customer's factory. Our engineers have arrived at the site to guide the installation and help train the customer's factory workers to skillfully operate the dryer. Our engineers will not return until the operation is

2023/11/02 14:25

This year Shine newly launched an economical small vertical dryer, which occupies a small area, is affordable, saves energy and electricity, and requires less labor. The output is 36m³/day. Our old customer in Myanmar purchased five units at one time. Production has recently been completed and

2023/10/27 10:16

The shine veneer dryer has the characteristics of large drying output, good effect, and easy maintenance. It has been unanimously recognized by customers and has been widely used. However, some customers always report that the efficiency of the wood chip drying equipment is not high. This is due to

2023/10/17 09:56