2 Deck Heat Thermal Oil Veneer Dryer Machine

In addition to the uniform moisture content,the veneer dried by the shine veneer dryer is flat with no buckle or end waviness,free of splits,cracks.Shrinkage is kept to a minimum during the drying process of the wood veneer dryer machine.So after drying, the veneer is in a very good condition before gluing for plywood making machine.

Product Description of 2 Deck Heat Thermal Oil Veneer Dryer Machine

This series of 2 deck heat thermal oil veneer dryer machine is one of the main machines in plywood production line. Shine veneer dryer is very suitable for wet clipping processing and drying thick veneer. 2 Deck Heat Thermal Oil Veneer Dryer Machine has merits of high output and low emission. veneer dryer machine equipped with new technology and advanced controlling system have been used for effective and quality drying veneers. Heat Thermal Oil as a type of hot air boiler, which is environmental friendly and energy saving. The most advantages of plywood veneer dryer is achieve lowest drying cost and perfect drying effect.

2 Deck Heat Thermal Oil Veneer Dryer Machine in Congo Customer Factory

2 Deck Heat Thermal Oil Veneer Dryer Machine

Features:

1. This model is a straight-through horizontal circulation 2 deck heat thermal oil veneer dryer machine. Its thermal cycle design draws on the advantages of advanced European dryer technology, and adopts an upright centrifugal fan with a volute (flow rate of 45,000 to 62,000 m3/ h).

2. The new type of heat exchanger and the rectangular variable-section spray box make the high-speed jet airflow acting on the surface of the veneer uniform. The hot air blowers in the heating chambers in the front and rear areas are arranged separately from left to right, so as to ensure that the dried veneer obtains a consistent final moisture content at each point.

3.In order to adapt to the humid tropical climate, the length of the cooling open section is appropriately lengthened to facilitate the cooling of the dried veneer and reduce the phenomenon of damp return.

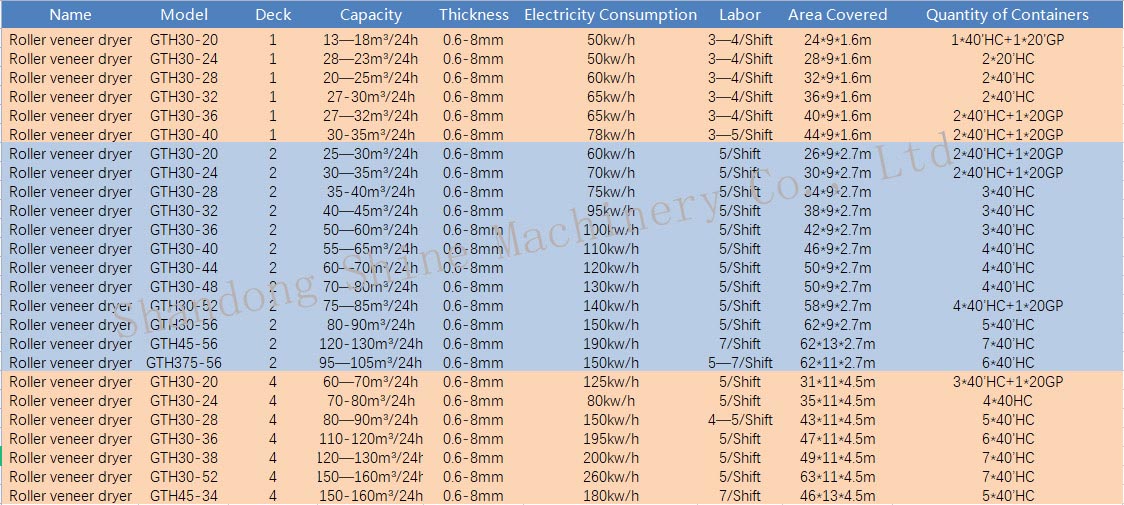

Product Parameters of 2 Deck Heat Thermal Oil Veneer Dryer Machine

Project Case

Our Certificate

FAQ

1.How much does it cost to dry 1m³ veneer?

About $12, including labor, fuel, electricity, will fluctuate with local prices.

2.How to choose a product that is most suitable for me?

A:Our company have professional engineer to select the most suitable product according to your capacity and areas, saving your time and cost.

3.Will it be difficult to install?

A: We will send professional engineers to guide. In remote situations, engineers will video assist workers with installation. There have been many remote success stories.

4.Can I see the real equipment and factory?

Yes. We can provide the location of the equipments that have put into production, and we contact and communicate with the users for you. Hence you can see our real equipment and its effects.