Heat Thermal Oil Veneer Drying for Plywood

The veneer drying process in a wood veneer dryer ensures that the dried veneer achieves uniform moisture content, remains flat without buckle or end waviness, and is free of splits, resulting in a surface in optimal condition for gluing. The entire machine is structured into two parts: a heating section and a cooling section. Each section is equipped with a heat exchanger, designed to maximize heat utilization and deliver the best drying performance. Available in various configurations, including mesh type, roller type, and a combination of mesh & roller type, the wood veneer dryer can be customized to meet specific production requirements.

Product Description of Heat Thermal Oil Veneer Drying

Heat thermal oil veneer drying is one of the most crucial phases of veneer production. The primary objective of the drying process is to produce high-quality, optimally dried veneer sheets with maximum efficiency. This is carried out by removing water from the sheet and decreasing the moisture content to an optimized level by using hot and humid air inside a dryer. By choosing industrial veneer drying, you improve veneer quality with a uniform drying result. As a result, you get high-quality. Its robust and sturdy structure guarantees a long lifetime and steady production with high efficiency. The proven technology gives you advanced production efficiency and capacity.

Heat Thermal Oil Veneer Drying

Our Services

Pre-sale services:

1) Provide a free consultation on all Core Veneer Dryer Machines.

2) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After-sales services:

1) 24-hour online service.

2) Provide the VIDEO on installing and debugging the equipment.

3) Provide technical exchange.

4) Door-to-door service is possible.

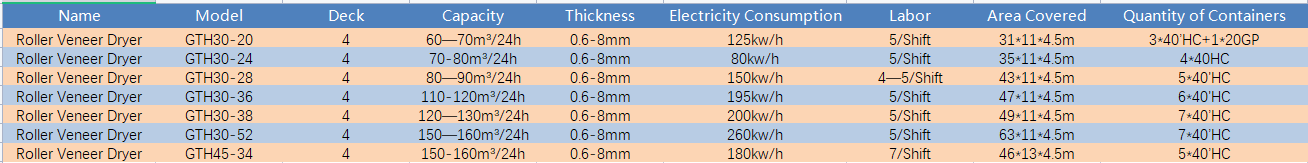

Product Parameters of Heat Thermal Oil Veneer Drying

High-Temperature Capability: Thermal oil furnaces can easily provide high-temperature heat sources exceeding 200°C, even reaching over 300°C, whereas steam systems struggle to achieve such temperatures under normal pressure. This is particularly suitable for thick veneers or high-density wood requiring rapid high-temperature drying.

Temperature Stability: Circulating within a sealed system, thermal oil releases heat uniformly through heat exchangers. This delivers exceptionally stable and consistent drying temperatures, eliminating the fluctuations inherent in direct flame heating or certain steam systems. Consequently, it ensures superior drying quality for veneers while minimizing issues like warping and cracking.

Customer Visiting and Exhibition

Shine High-Performance Veneer Drying Solutions — Empowering Your Product Quality & Production Efficiency

Customers from all over the world visit

Our Factory

Our production facility integrates R&D, manufacturing, testing, and after-sales services under one roof, equipped with modern standardized workshops and advanced machining centers. This ensures every step—from steel plate cutting to complete unit assembly—is executed under our stringent quality control system, guaranteeing both factory standards and delivery capability.