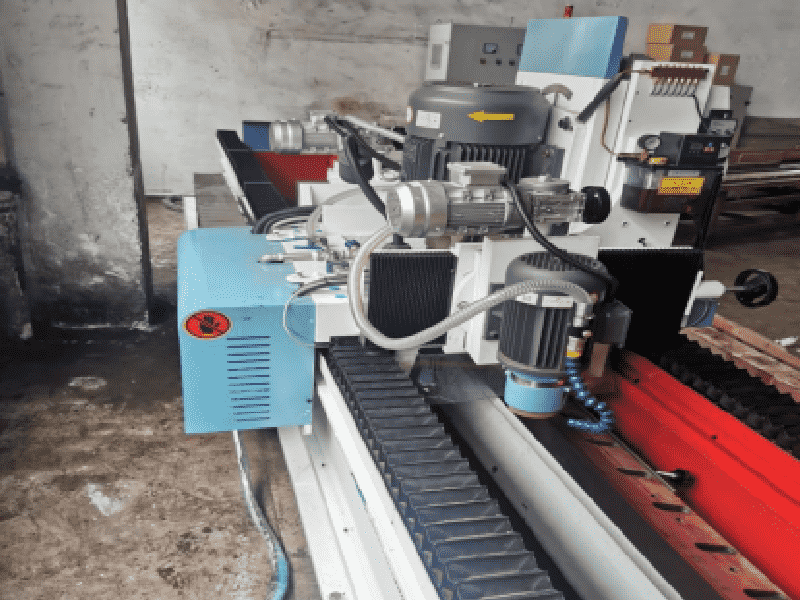

Shine Professional Woodworking Blade Sharpener for Sale

Knife grinding: Repair the edge of worn-out knives and restore their sharpness.

Angle Adjustment: The grinding angle can be adjusted according to the need, applicable to different types of knives.

Polishing: Some of the high-end sharpening machines are equipped with a polishing function, which improves the surface finish of the tool.

Auto-detection: Some machines are equipped with an auto-detection function, which can detect the degree of tool wear and adjust the grinding parameters automatically.

Core Features of the Grind Machine

High Precision: Adopting high-precision grinding technology ensures the sharpness and service life of the tools.

High Efficiency: Automated equipment can quickly complete grinding tasks and increase productivity.

Versatility: This can be applied to many types of tools, such as planer cutters, milling cutters, saw blades, and so on.

Durability: High-quality materials and construction ensure a long service life.

Safety: Equipped with guards and emergency stop function to ensure safe operation.

The Main Types of Grinding Knife Machines

1.1 Manual Knife Sharpener

Characteristics: Simple operation, low price, suitable for small woodworking workshops or personal use.

Application Scenario: Suitable for grinding a small number of knives, such as hand planer knives and chisels.

Disadvantages: lower efficiency, reliance on manual operation, and precision may not be as good as automatic equipment.

1.2 Automatic Knife Sharpener

Features: High degree of automation, can automatically complete the grinding, angle adjustment, and polishing operations.

Scenario: Suitable for grinding large quantities of tools, such as planer blades, milling cutters, and so on.

Advantages: High efficiency, high precision, and labor-saving.

1.3 CNC Knife Grinding Machine

Features: Adopting computer numerical control technology, it can realize high-precision and multi-angle grinding.

Scenario: Suitable for grinding tools with high precision requirements, such as complex-shaped milling cutters, engraving cutters, etc.

Advantages: extremely high precision, programmable operation, suitable for complex tools.

1.4 Portable Knife Sharpener

Features: Small size, easy to carry, suitable for on-site use.

Scenario: Suitable for tool grinding in outdoor or temporary workplaces.

Advantages: Flexible, suitable for mobile work requirements.

Technical Parameters of Knife Sharpening Machines

| Maximum Grinding Length | 800mm |

| Work Set Area | 800*160mm |

| Grinding Wheel Size | 200*100*50mm |

| Grinding Accuracy | ≤0.08mm/m |

Operating Voltage | 380V 50HZ |

| The Tool Machine Whets A Head To Go Back And Forth Speed | Around 14m/min |

Whet An Adjustable Angle | ±10° |

| Work Set Adjustable Angle | ±90° |

Total Power | Around 4.5 kW |

| Total Weight | 450kg |

Application Scenario of the Grind Knife Machine

Woodworking workshop: for grinding planer blades, milling cutters, saw blades, etc.

Furniture manufacturing: for the repair and maintenance of knives used in the production of furniture.

Construction industry: for sharpening woodworking tools such as chisels, planer knives, etc.

Personal workshop: For woodworking enthusiasts, for grinding hand tools.

Company Strength

In the pursuit of high-efficiency environmental protection and quality in the wood processing industry, as a veneer dryer manufacturer, Shine has become a bright star in the industry with its excellent performance, advanced technology, and intelligent design. We know that drying is not only the key step to ensure the stability of the veneer in every process of veneer but also the foundation to improve the quality of the product and prolong its service life. Therefore, Shine has created a series of high-efficiency veneer dryers aiming to bring an unprecedented drying experience to global wood processing enterprises.