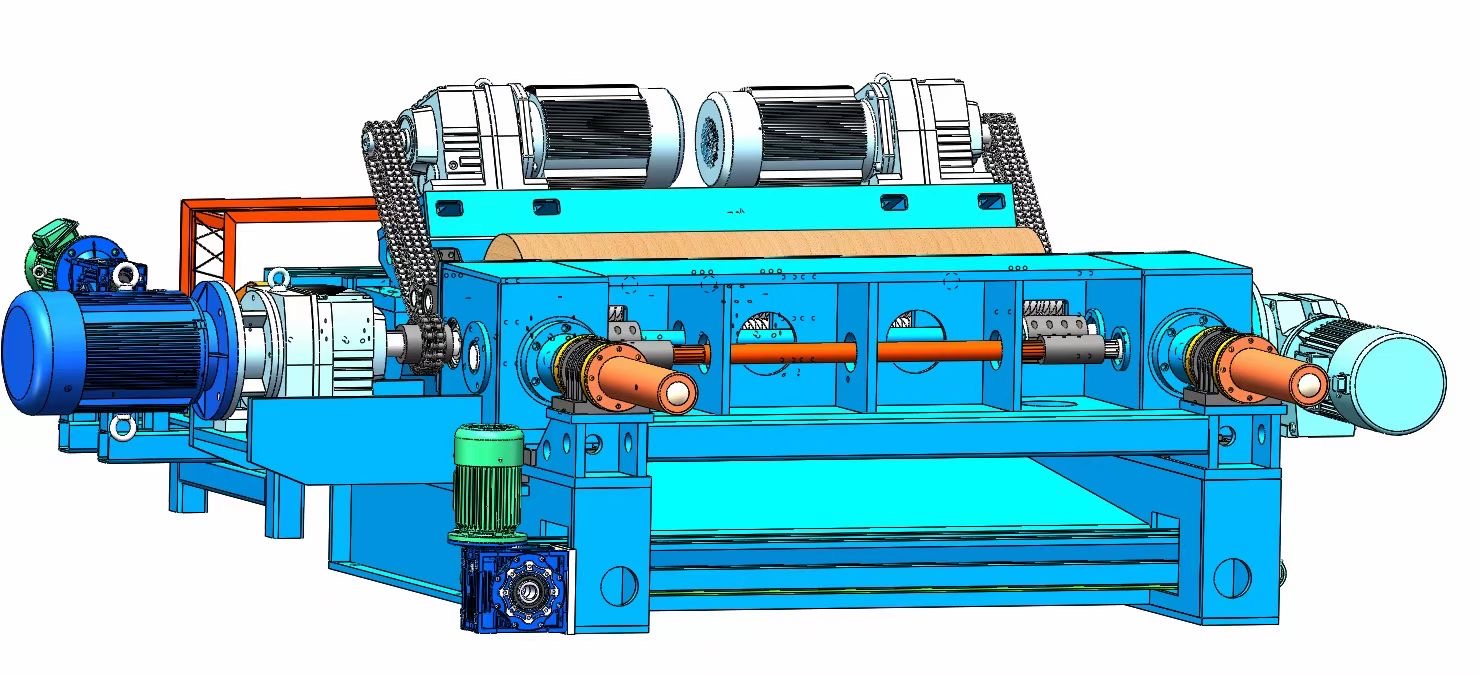

Rotary Cut Veneer Peeling Machine (Non-Spindle)

Shine Machinery Rotary Veneer Peeling Machines: Precision Engineering for Efficient Eucalyptus Veneer Production

In the fast-paced world of wood veneer manufacturing, consistency, durability, and adaptability are non-negotiable—especially for high-demand materials like eucalyptus veneer. At Shine Machinery, we’ve redefined the art of rotary veneer peeling with our state-of-the-art rotary cut veneer machines, engineered to transform raw eucalyptus logs into premium, uniform veneers with unmatched precision and efficiency. Whether you’re scaling production in Africa’s thriving forestry hubs or optimizing operations globally, our peeling machines are built to deliver.

One-Piece Welded Frame: Precision Engineered for Stability

At the core of Shine’s rotary veneer peeling machines lies a groundbreaking manufacturing process: integrated double-row and frame welding. Unlike traditional methods that assemble pre-welded components, we weld the double-row structure and frame together first, then machine them as a single unit. This “one-piece” construction eliminates alignment errors, ensuring:

Microscopic precision: Tolerances as tight as ±0.05mm for consistent veneer thickness—critical for high-end furniture, flooring, and construction applications.

Unmatched stability: The rigid steel plate frame (not channel steel) resists vibration and flexing, even during high-speed peeling of dense eucalyptus logs. This durability reduces long-term wear and extends machine lifespan.

Dual-Drive System: Effortless, Adaptive Power

Peeling eucalyptus logs—whether small saplings or large-diameter trunks—requires power and finesse. Shine’s dual-drive system automates speed regulation based on log diameter, making operation effortless and efficient:

Automatic speed adjustment: Sensors detect log size and adjust rotation speed in real time, ensuring smooth, even peeling without manual intervention.

Energy-efficient performance: Optimized power distribution reduces energy consumption by up to 25% compared to single-drive models, lowering operational costs.

Auto-Adjustable Blades: Consistency That Lasts

Maintaining uniform veneer thickness is the hallmark of premium eucalyptus production. Shine’s machines eliminate guesswork with intelligent blade adjustment technology:

Dynamic blade sizing: As the log diameter increases during rotation, the blade widens automatically to match the log’s profile—ensuring even thickness from the center to the edge.

Extended blade life: Precise control reduces uneven wear, extending the interval between sharpening. While traditional machines require resharpening every 30–40 cubic meters, Shine’s system stretches this to 40–50 cubic meters, minimizing downtime.

Custom Solutions for Every Eucalyptus Producer

No two eucalyptus plantations are alike—and neither are their veneer needs. Shine Machinery specializes in tailored rotary veneer peeling solutions, designed around your specific requirements:

Log species optimization: Engineered for eucalyptus (a dense, fibrous wood), but adaptable to other hardwoods like birch or rubberwood.

Log diameter range: Configurable settings for small (≤30cm) to large (≥80cm) logs, maximizing yield from every tree.

Veneer thickness control: Adjustable from 0.3mm (decorative) to 5mm (construction-grade), meeting diverse market demands.

Global Leadership in Eucalyptus Veneer Production

Today, Shine’s rotary veneer peeling machines are the go-to choice for eucalyptus producers worldwide—especially in Africa, where the climate and soil make it a cornerstone of the forestry industry. Our 4ft, 5ft, 6ft, 8ft, and 9ft models are trusted by clients across the continent, who report:

30% higher throughput: Faster rotation and adaptive controls reduce idle time, boosting daily output.

20% lower waste: Precision peeling minimizes offcuts and rework, maximizing log utilization.

Longer machine life: Robust steel plate frames and durable components withstand heavy daily use, even in harsh conditions.

Shine Machinery: Your Partner in Eucalyptus Veneer Excellence

As the global leader in rotary cut veneer technology, Shine Machinery is committed to innovation that drives your success. Whether you’re scaling up production, improving quality, or reducing costs, our machines deliver the precision, power, and adaptability you need to thrive in the eucalyptus veneer market.