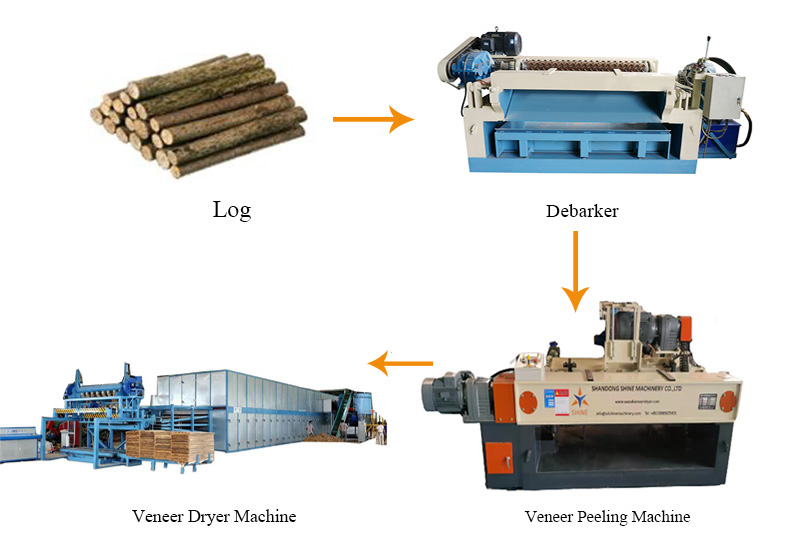

Veneer Production Process

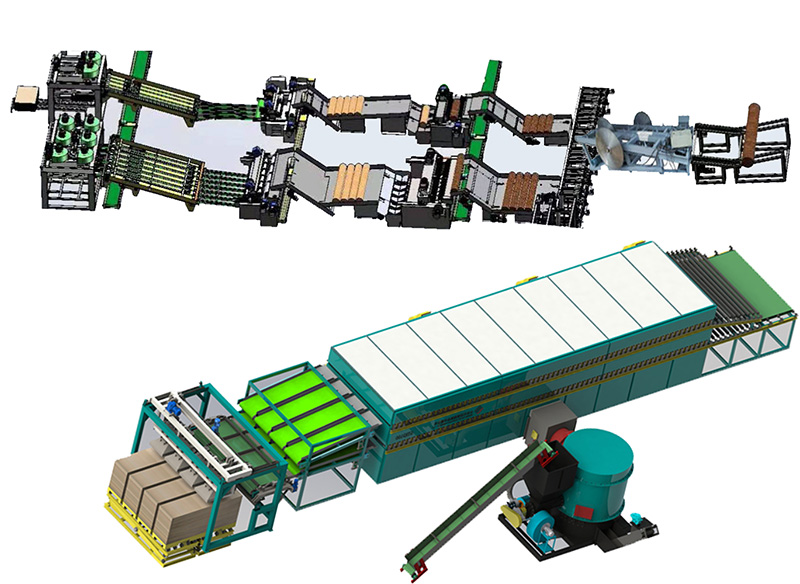

Shine offers everything from individual drying plants with manual loading to complete veneer lines with automatic loading and stacking systems. We provide the wood manufacturing industry with state-of-the-art veneer drying technology including the highest possible energy efficiency.

The dried veneers can be used in the furniture industry, packaging, formwork, flooring and other interior design, etc. The peeled veneers dried on our drying lines are used in the manufacture of plywood and LVL (Laminated Veneer Lumber) (Laminated Veneer Lumber, LVL).

Veneer Production Process

Many customers have reported that the dryer will encounter clogging and long production downtime. This problem will also occur on our old equipment. Now the new dryer developed by Shine not only does not have these problems, but also has the same power as the whole machine. It is 35% lower than before. The fan adopts the latest axial flow fan, automatic control and frequency conversion control system, which can accurately control the final moisture content. The unique heat exchange system can evenly distribute hot air to the veneer, fully improving the energy consumption The utilization rate is high, so that the moisture content of the veneer after drying is uniform, flat, without wrinkles or end ripples, without cracks, and the surface is in good glued state, which reduces waste to a minimum.

Regarding the drying temperature: when the veneers enter the dryer, their temperature is 20-30°C, and when they leave the dryer and enter the conveyor belt to enter the cooling section, their temperature is 140-180°C.

About customer cases: We have exported to more than 20 countries and regions such as Thailand, Laos, Malaysia, Cambodia, Brazil, Latvia, South Africa, South America, Russia, etc., with the lowest drying cost (fuel + electricity + labor), high output , low energy consumption and perfect drying quality, Shine's veneer dryer and other equipment are highly recognized by customers.

About our services:

Shine can provide one-stop services and solutions to bring maximum benefits to customers and meet your requirements, we can provide you with a comprehensive service concept, our personnel are experts in their respective fields, and with deep product-related expertise Standing out, we commission your equipment according to plan and follow our service commitment throughout the entire period of use. In addition to spare parts supply and upgrades, we also ensure the equipment performance and sustainability of your plant.

The construction and commissioning of a new veneer production line is only the first step in establishing a good customer relationship. Professional service in day-to-day operation is just as important: We want your investment to profit without any disruptions – that's why our engineers guide and support you throughout the entire lifecycle of your plant.

Video of Shine Customer Case

Specific services:

Pre-sale services:

1) Provide the free consultation of all plywood machinery

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging(Technical phone:++8615806625431)Door to door service is possible