Compact Veneer Dryer Systems

At our core, we are a customer-centric manufacturer dedicated to providing tailored drying solutions for the global wood processing industry. We understand that every client's operation is unique, which is why we offer complete ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services for our vertical veneer dryer systems. Whether you require a custom-designed machine to fit specific factory dimensions, need unique features for specialized veneer types, or wish to apply your own branding, our engineering team collaborates with you to bring your exact requirements to life. This flexibility ensures that the vertical veneer dryer you receive is not an off-the-shelf product, but an optimized solution designed for your maximum productivity and efficiency.

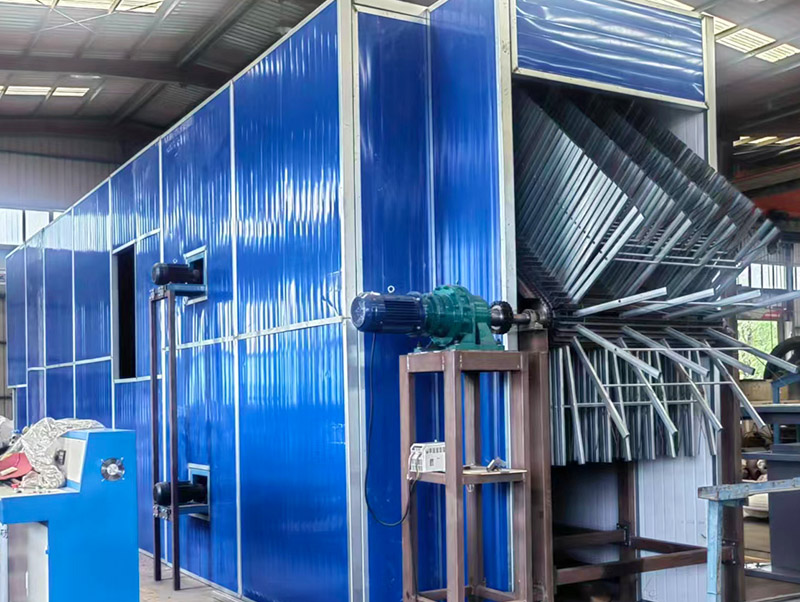

Shine Machinery Veneer Dryer – Compact, Cost-Effective, and Powerful

For businesses seeking a space-saving yet high-performance drying solution, Shine Machinery’s veneer dryer offers an ideal combination of compact design and operational efficiency. Its small footprint makes it particularly suitable for workshops and factories with limited space, while the efficient heating system ensures strong drying capability. The fully automatic control system streamlines the drying process, significantly reducing labor requirements and improving productivity. Designed for optimal thermal efficiency, the equipment minimizes energy waste, providing customers with a cost-effective drying solution. Key advantages include space savings, low operating costs without sacrificing performance, consistent drying results for enhanced product quality, long-term reliability with minimal maintenance, and flexible adaptation to various wood species.

Shine Machinery’s veneer dryer combines performance, efficiency, and affordability — the perfect investment for your veneer drying needs.

Product Parameters of Veneer Dryer

Model | FBH30-20 |

Moisture Content(%) | Fresh veneer to within 20% |

Capacity(m³/H) | 1.2-1.5 |

Overall Size | 20 X 7 X 4 |

Hot Air Blower(KW) | 1.5kw X 6set=9KW |

Traction Motor(KW) | 4KW |

Intake Air Blower(KW) | 7.5KW |

Internal Burner Blower (KW) | 1.1KW |

Oil Station Power | 2.2KW |

Water Pump Power | 2.2KW |

Chain Conveyor | 2.2KW |

Infeed Conveyor Belt

| 2.2KW |

Side Entry Feeding

| 2.2KW |

Veneer Collecting | 2.2KW |

Cooling Blower (Above burner) | 0.75kw*2set=1.5KW |

Total Power(KW) | 36.3KW |

Exhibition and Customer Visiting

Leveraging its in-house R&D team, Shine continuously optimizes hot air circulation, temperature-humidity balance, and energy-saving designs. We provide customized veneer dryer configurations and supporting solutions tailored to different wood species, specifications, and production capacity requirements, helping customers effectively boost veneer yield and reduce drying costs.

The Factory

Continuous technological innovation, customized drying solutions

Packaging & Shipping

Shine wood veneer dryers have been reliably exported to numerous countries and regions across Southeast Asia, Europe, South America, and beyond. Regardless of destination climate or environmental conditions, our packaging and delivery standards have proven their worth in practice, earning consistent recognition from international customers.