Continuous Veneer Dryer

Continuous veneer dryer is a new generation wood veneer drying machine. It adopts the latest international pressure contact veneer drying technology to ensure the veneer is heated evenly. It can be used to dry rubber wood, eucalyptus, birch, teak, all kinds of hardwood and softwood veneer, etc.

Continuous Veneer Dryer

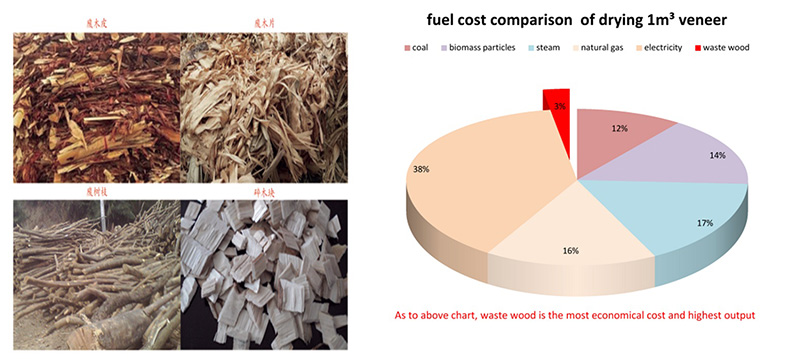

Continuous veneer dryer is ideal for drying wood veneers, and the veneer drying machine is one of the main equipment in plate production. By adopting the latest international pressure contact veneer drying technology. Shine veneer roller dryer has the features of high productivity, energy efficiency, the lowest drying cost, and perfect drying effect. A veneer dryer machine can dry veneers of various thicknesses and various moisture contents. The quality of the wood veneer dryer directly affects the quality of the veneer and glued products. The design of the hot air continuous roller press is based on the most advanced continuous pressure contact veneer drying technology in the world. Our biomass burner, which can use waste wood as fuel and burn all kinds of waste wood directly to reduce fuel costs to the most. Veneer dryers offer great advantages over conventional veneer drying systems.

Main Features of Continuous Veneer Dryer

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high-temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, has ess ancillary equipment, is convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

Product Parameters of Continuous Veneer Dryer

Model No | GTH30-28 |

Working Width | 3m |

Deck | 1 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 24m |

Cooling area length | 4m |

Veneer thickness | 1.7 |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | About 22-27m³/day |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(6pc) |

Traction motor | Power: 5.5KW,frequency control(1pc) |

Cold air blower | Power:5.5KW(1pc) |

Air intake fan | Power: 11KW(1pc) |

2ton biomass burner | Power: 15KW |

Total power | 70KW |

Actual electricity consumption | About 50kwh per hour |

Space covered about | 32m× 9m×2m |

Exhibition and Customer Visiting

Shine Machinery cordially invites you to visit our factory for an on-site inspection or attend industry exhibitions to experience firsthand the exceptional performance and innovative technology of our next-generation wood veneer dryers! We welcome your scrutiny and exchange with an open attitude, exploring together the boundless possibilities of efficient drying.

The Factory

Pioneering “Four-Layer Counterflow Heat Exchange” technology reduces energy consumption by 40%

Developed an intelligent adaptive temperature control system with moisture content accuracy of ±0.5%

Biomass gas compatibility design addresses environmental challenges in high-pollution areas

Packaging & Shipping

Dear Valued Customer, Thank you for choosing Shine Wood Veneer Dryer! We understand that safe equipment delivery is the foundation of our partnership. Therefore, we have established a standardized, international packaging and shipping system to ensure your equipment arrives at the installation site worry-free from factory to destination!