Automatic Veneer Dryer

Buying a dryer is just the start. Shine Machinery goes the extra mile to ensure your machine works seamlessly, with a complete after-sales service system that includes:

24-hour online support: Got a question? Our technical team is here around the clock to troubleshoot, offer tips, or guide you through adjustments.

On-site installation & training: Our engineers will travel to your facility to set up the dryer, train your staff, and ensure everything runs smoothly from day one.

Regular visits & spare parts supply: We don’t just disappear after installation. Our team checks in periodically to maintain your dryer, and we stock ample spare parts to minimize downtime.

When it comes to drying wood veneers, one size doesn’t fit all. That’s why Shine Machinery’s automatic wood veneer dryer stands out—it’s designed to adapt to your unique requirements, whether you’re working with eucalyptus, birch, pine, or other wood types.

2-Deck Roller Veneer Dryer: Energy-Efficient

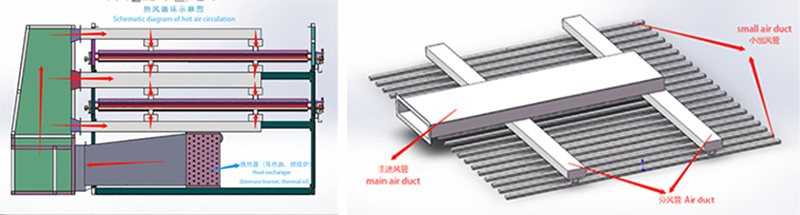

For those prioritizing cost and energy savings, Shine’s 2-deck roller veneer dryer is a game-changer. Powered by a new-generation axial flow fan, this model reduces the overall power consumption of the automatic dryer by up to 38%, making it one of the most energy-efficient options on the market. Here’s why it’s a smart choice:

Wide material compatibility: Whether drying thin decorative veneers (0.5mm) or thick industrial planks (8mm), this dryer handles them all—eucalyptus, birch, pine, and more.

Flexible sizing: Choose from multiple length and width options to fit your workshop layout. No more cluttering your space with oversized equipment.

Customizable Configurations

Shine’s automatic veneer dryer isn’t a “one-model-fits-all” machine. We understand that drying needs vary—some workshops need compact units for small batches, while others require high-capacity systems for large-scale production. That’s why we offer multiple drying configurations tailored to your specific needs:

Adjustable length, width, and layers: Whether you need a 2-deck roller dryer for tight spaces or a multi-layer model for high-volume output, our engineers will design and build it to match your workspace, budget, and production goals.

Durable, long-lasting design: Made with robust materials and engineered for continuous use, our dryers are built to withstand the rigors of daily operations—no more frequent breakdowns or costly repairs.

Product Parameters of 2 decks Automatic Veneer Dryer

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 108.5KW |

Actual electricity consumption | About 76kwh per hour |

Covered Space of the whole machine | 46M X 9M X 3M |

The installation

4 decks 40m plywood veneer dryer was smoothly installed in Brasov, Romania, this dryer is eqyipped with Thermal oil heat source. Only 21 days were used for the overall installation.

Packaging & Shipping

Shine isn’t just another machinery brand—we’re your partner in success. Our automatic wood veneer dryer is backed by years of R&D, real-world testing, and a team of experts ready to support you. From troubleshooting to routine maintenance, we’re here to keep your dryer running smoothly, so you can focus on what you do best: making great wood products