Hot Air Veneer Dryer Machine

Type: Roller Veneer Dryer

Working Width: 3m

Veneer thickness: 0.8-8mm

Heating Area Length: 32m

Drying capacity (m³/day) : 110-120

Veneer Water Moisture: Fresh veneer to about 0-15%

Cost: 6-12$/m3 (Labor+Fuel+Electricity)

Heat Source: Biomass Burner (Other options available)

Hot Air Veneer Dryer Machine

Shine veneer dryer uses the biomass burner as the heat source of the roller dryer. The hot air emitted from the heat exchangers can be blown to the surface and back of the fresh veneer to achieve the veneer drying effect. The working width and length of the wood veneer drying machine can be customized according to the specific veneer drying capacity requirement needed by the different customers. Shine heat exchanger adopts step-by-step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer.

Shine's newly upgraded plywood dryer machine has a 35% reduction in power, minimizing the power consumption of the entire equipment. It adopts a fully automatic control and frequency conversion control system, which can automatically adjust the transmission speed and temperature according to different veneer thickness and moisture content to achieve the ideal drying effect. Manual, semi-automatic, and fully automatic configurations are available for you to choose from. Meet different wood processing needs.

Product Parameters of Hot Air Veneer Dryer Machine

Model No | GTH30-36 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 32m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which ensures a consistent moisture content. |

Drying capacity (m³/day) | 110 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(32pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10-ton biomass burner | Power: 16.5KW |

Total power | 212.5KW |

Actual electricity consumption | About 149kwh per hour |

Overall Dimension(L*W*H) | 47m×11m×3.5m |

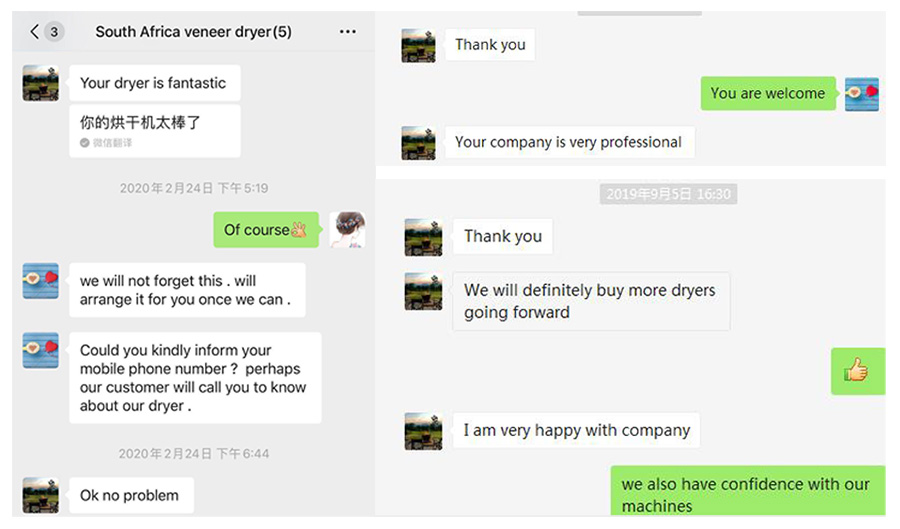

The customer evaluation

We thank our customers feedback and are happy to know they are satisfied with the performance of the roller veneer dryer. We believe our dryer machine can help customers dry more qualified veneer and make more profits for our dear customers.

Packaging & Shipping

Rollers, insulation board, and main frame are packed in nude while veneer dryer parts are packed into plywood crates and wrapped with film. Each container is filled in full in order not to waste the space and save sea freight for customers.