Plywood Dryer

Our Plywood Veneer Dryer (Type: Roller Veneer Dryer) is engineered for high-efficiency plywood veneer making processes, featuring a 3m working width and accommodating veneer thickness of 0.8-8mm to handle diverse production needs. With an extended 44m heating area length, this Plywood Veneer Making Dryer delivers an impressive drying capacity of 70-80m³/day, efficiently reducing veneer water moisture from fresh state to 0-15% for optimal plywood manufacturing quality.

SHINE plywood dryer provides you with a one-stop solution. The dried veneer has uniform moisture content, is flat, has no wrinkles or end ripples, no cracks, and has a good surface glued state. The power of the whole machine is reduced by 35%, and the power consumption is greatly reduced compared with the traditional veneer dryer. Designed for cost-effective operation, our Plywood Dryer maintains low production expenses at just 6-12$/m³ (including labor, fuel, and electricity), supported by flexible heat source options including a standard biomass burner (with gas, steam, or electric alternatives available).

Product Parameters of Plywood Dryer

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee that the moisture content is consistent. |

Drying capacity (m³/24h) | 70-80cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6-ton biomass burner | Power: 16.5KW |

Total power | 119.5KW |

Actual electricity consumption | About 84kwh per hour |

Covered Space of the whole machine | 50M X 9M X 3M |

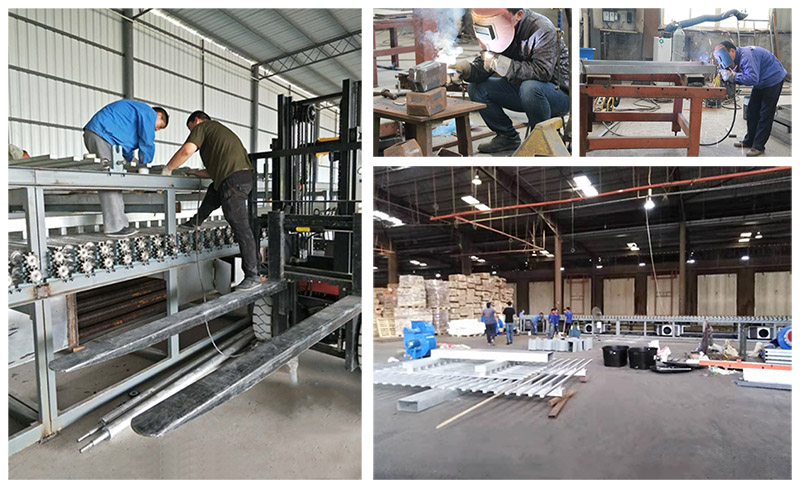

The installation

The standard installation period for Shine wood veneer dryers is approximately 40 days. This efficient installation process is made possible by our mature modular design and professional engineering team support.

The Factory

Waste heat recovery system (30% reduction in energy consumption)

Axial flow fan (38% reduction in total power consumption)

Packaging & Shipping

Shine Machinery has a mature international logistics system to ensure that single-board dryers are delivered to customers around the world in the safest and most economical way. We use standardized packaging and professional container loading solutions to maximize the integrity of equipment transportation while optimizing sea and land transportation costs.