Biomass Dryer Machine

If you’re looking for a way to dry wood veneers that’s both eco-friendly and wallet-friendly, Shine Machinery’s biomass wood veneer dryer is the answer:

Biomass dryer machine can keep the veneer smooth after drying. Biomass drying machine equipped with water circulation system, which can save energy and improve efficiency. Biomass burner as heat for 40m 2 deck veneer drying machine, bark and other tree waste can be used as the fuels for veneer drying line, saving fuel cost significantly. The drying capacity of 40m 2 deck dryer can achieve 2.5m³ per hour. The composite cost of Shine biomass drying machine is only USD 6-12/per cubic meter.

Smooth Veneers, No Compromises

One of the biggest headaches in veneer drying? Warped or cracked sheets. Shine’s biomass dryer solves that. Thanks to its precise temperature control and even heat distribution, every veneer dries flat, smooth, and free of defects. No more “buckling” (that annoying upward curl) or “end waviness” (side-to-side rippling)—just pristine sheets ready for gluing, laminating, or coating.

Save Energy, Boost Efficiency with Water Circulation

Shine’s biomass dryer isn’t just about drying—it’s about smart drying. Equipped with a water circulation system, it recovers residual heat from the drying process and reuses it. This means less energy wasted on heating fresh air and more efficient use of every BTU. The result? Lower operational costs and faster drying cycles, so you get more done in less time.

Burn Waste, Save Money: Biomass Fuel That Makes Sense

Why spend big on fossil fuels when you can use what’s already lying around? Shine’s biomass dryer runs on tree bark, sawdust, and other wood waste—materials that would otherwise end up in landfills. By turning trash into fuel, you slash fuel costs by 40–50% compared to traditional gas or electric dryers. It’s not just good for your bottom line; it’s good for the planet too.

40m 2-Deck Dryer: High Capacity, Low Cost

Need to dry a lot of veneers? Shine’s 40m 2-deck veneer dryer is built for scale. With a drying capacity of 2.5m³ per hour, it handles large batches without breaking a sweat. And here’s the kicker: the composite drying cost (labor + fuel + electricity) is just $6–12 per cubic meter. That’s cheaper than most traditional models, making it a no-brainer for busy workshops or factories.

Product Parameter of Biomass Dryer Machine

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 109KW |

Actual electricity consumption | About 76kwh per hour |

Covered Space of the whole machine | 46M X 9M X 3M |

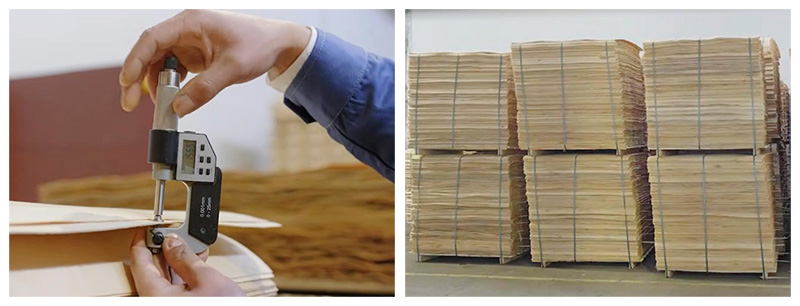

Customer Products

Using Shine Dryer, the results? Veneers with uniform moisture content (no dry spots, no spongy areas), which means stronger glue bonds and fewer defects in your final products.

Exhibition and Customer Visiting

Shine isn’t just a machinery supplier—we’re your partner in success. We listen to every customer needs, adapt our solutions, and stand by our products—because customer’s success is our success!

Factory

Decades of R&D: We’ve spent years refining our designs to balance efficiency, durability, and cost-effectiveness.

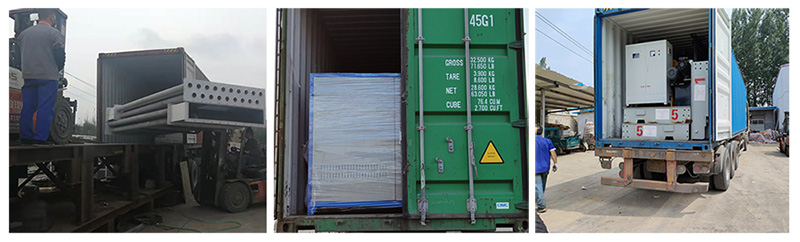

Packaging & Shipping