Roller Veneer Drying

Roller veneer drying has a variety of different drying configurations to suit a variety of drying needs are available.The length, width, and layers of the core veneer dryer can be designed and made for customers.The veneer drying line is durable in use and long service life.Shine Machinery is responsible for providing users the best drying solutions,not just the veneer dryer itself to ensure the higher drying capacity,energy efficiency,and less fuel cost.In line with the specific production capacity,the continuous veneer drying machine can be customized to meet customers' needs.

Roller Veneer Drying

Shine roller veneer drying adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect. Equipped with automatic veneer feeder and automatic collection system, which not only improves the drying efficiency but also saves labor cost mostly.

Roller veneer drying can keep the veneer smooth after drying. veneer dryer machine equipped with water circulation system, which can save energy and improve efficiency.

Advantages of Roller Veneer Drying

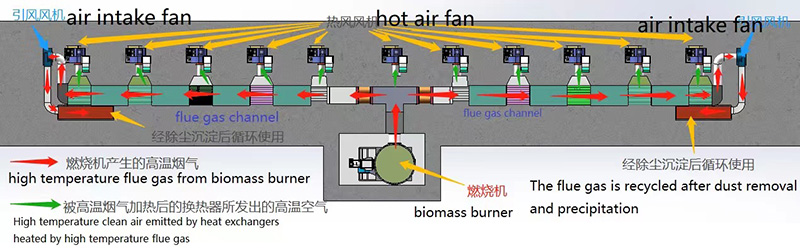

1、The hot air fan and cold air fan of the dryer adopt the latest axial flow fan, which reduces power consumption and greatly reduces the power of the whole machine, which can further reduce the later operation cost.

2、The Shine heat exchanger adopts step-by-step heat exchange. The specifications of each heat exchanger are different, and the hot air inside can be evenly distributed to the single board. After drying, the moisture content of the veneer is uniform, smooth, without wrinkles or end ripples, without cracks, and the surface is in good glued state.

3、The roller veneer drying adopts frequency conversion speed regulation, which can adjust the feeding speed according to your veneer thickness and moisture content, so as to achieve the ideal drying effect.

6、The fuel source can be waste wood or bark after peeling, which can greatly reduce fuel costs for users.

5、Perfect after-sales service system, 24-hour online service, remote operation, so that customers can rest assured after installation. Regular follow-up services for old customers, sufficient and timely supply of spare parts.

Product Parameter of Roller Veneer Drying

Model No | GTH30-44 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 40m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 60-70cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(10pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 69KW |

Actual electricity consumption | About 114kwh per hour |

Covered Space of the whole machine | 50M X 9M X 3M |

Certification

Customer Visiting

Factory

Packaging & Shipping