Veneer Jet Dryer

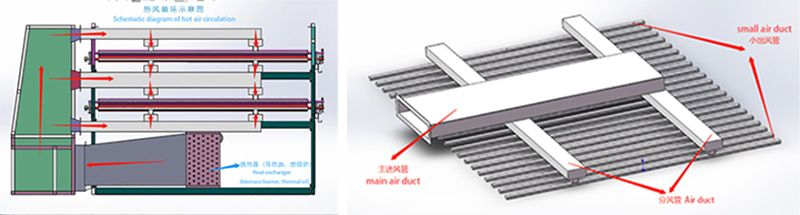

Veneer Jet Dryer is a new generation wood veneer drying machine. It adopts the latest international pressure contact veneer drying technology to ensure the veneer is heated evenly. It can be used to dry rubber wood, eucalyptus, birch, teak, all kinds of hardwood and softwood veneer, etc.

Veneer Jet Dryer

Shine 2 deck veneer core dryer machine is widely valued for the lowest operation cost, high drying capacity, and energy-efficient as well as high-quality veneer output. It is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad. The composite cost is only about $6-12/cubic meter for fuel and electricity. A standard wood veneer dryer is composed of heating chambers and cooling chambers. The veneer roller dryer allows automatic feeder devices, which can save labor costs greatly. Equipped with a biomass burner, all kinds of waste wood, such as waste bark, waste veneer, can be burned as fuel directly, even if the waste wood is wet. The temperature inside the biomass veneer dryer machine is 40-60℃ higher than traditional steam or thermal oil-heated roller dryers.

Product Parameter of Veneer Jet Dryer

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 70-80cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6-ton biomass burner | Power: 16.5KW |

Total power | 119.5KW |

Actual electricity consumption | About 84kwh per hour |

Covered Space of the whole machine | 50M X 9M X 3M |

Customer Case

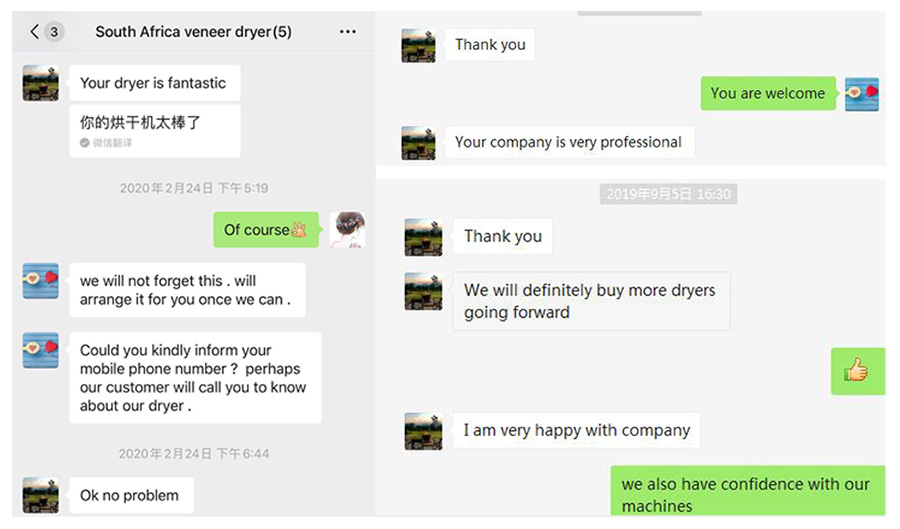

On the global wood processing scene, Shine rapid veneer dryers are becoming the preferred choice for numerous enterprises seeking to enhance quality and boost efficiency. From large forestry groups to specialized veneer manufacturers, countless customer cases attest to the outstanding performance and reliable quality of Shine wood drying equipment.

Customer Feedback

The biggest headache used to be the labor challenges in the drying process—manual loading and unloading were inefficient and costly. Since introducing Shine's fully automated feeding and receiving system for the drying line, we've saved 3-4 workers per shift. Plus, 24/7 continuous production is no problem. We recouped the equipment cost difference in just over a year—the efficiency boost is truly remarkable!

The Factory

Shine Machinery, as a professional manufacturer of veneer dryers, possesses robust factory capabilities and strong production capacity. Equipped with advanced production facilities and a professional technical team, we are committed to providing customers with high-quality, high-efficiency wood drying equipment.