Plywood Roller Dryer Machine

In the competitive plywood and woodworking industry, optimizing veneer drying processes is essential for ensuring quality, reducing energy costs, and enhancing efficiency. Shine Machinery’s advanced Veneer Dryer Machine delivers superior Veneer Drying performance with customizable solutions, setting new industry standards. The Veneer Dryer Machine by Shine Machinery is the ideal choice for efficient and high-performance wood veneer drying.

Plywood Roller Dryer Machine

The 2-deck veneer dryer stands out as a cost-effective, energy-saving, and power-efficient solution for modern woodworking operations. Designed with industrial efficiency in mind, this dryer leverages a step-by-step heat exchange system to optimize drying performance while minimizing operational costs.

At its core, the dryer’s graded heat exchange design sets it apart. Unlike traditional single-stage dryers, the 2-deck system divides the drying process into two distinct stages, each tailored to specific moisture reduction goals. The heat exchangers in these sections are engineered with varying specifications—from the initial high-efficiency preheating zone (equipped with compact, high-conductivity fins) to the final precision-drying zone (featuring larger surface area plates for gradual moisture extraction). This staged approach ensures that heat is applied incrementally, avoiding sudden temperature spikes that could warp or crack delicate veneers.

A key innovation lies in its uniform hot air distribution mechanism. The dryer integrates a multi-channel airflow system, where heated air is channeled through precisely designed nozzles and guide vanes. This setup ensures even air circulation across every layer of veneer, eliminating "hot spots" or uneven drying zones. As a result, the moisture content of the dried veneer remains consistently balanced—typically within an optimal range of 8–12%—with no localized areas of over-drying or residual dampness.

Key features include

(1) Customized one-stop service for tailored needs;

(2) Energy-saving design with axial flow fans, reducing power consumption by 38%

(3) Stable operation and low failure rate for reliable performance

(4) High-quality imported components and thicker steel for durability

(5) Professional factory production ensures precision and excellence

Product Parameters of Roller Dryer Machine

Model No | GTH30-56 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 52m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, ensuring a consistent moisture content. |

Drying capacity (m³/24h) | 85-95cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(13pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 15KW(2pc) |

6-ton biomass burner | Power: 16.5KW |

Total power | 138.5KW |

Actual electricity consumption | About 97kwh per hour |

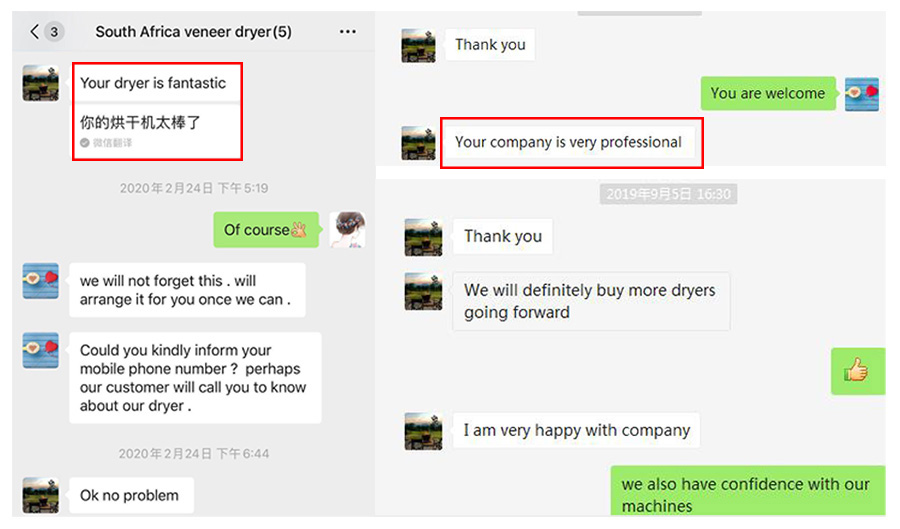

Customer Case of Veneer Dryer

Shine's star model of dryer is widely used in South China, Europe, Southeast Asia, for example, in Guangdong, China; in Riga, Latvia; in Kalasin, Thailand, etc.

The customer evaluation

"We are extremely satisfied with Shine’s Veneer Dryer Machine! The drying efficiency is outstanding, and the energy-saving design has significantly reduced our operating costs. The machine runs stably with minimal downtime, and the uniform heat distribution ensures consistent veneer drying quality. The customizable settings allow us to adapt to different wood types effortlessly. Highly recommended for anyone in the plywood industry seeking a reliable, high-performance Veneer Drying Machine!"

Our Services

Pre-sale services:

1) Provide a free consultation on the plywood production lines

2) According to the clients' special requirement, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas, install and debug the equipment.

3) Train the first-line operator.

After-sales services:

1) 24-hour online service.

2) Provide the VIDEO on installing and debugging the equipment.

3) Provide technical exchanging(Technical phone:+8615806625431)Door to door service is possible.

The Factory

Shine factory specializes the veneer dryer manufacturing since 1999, also we provide customers the complete services for plywood production.

Packaging & Shipping

At Shine Machinery, we ensure a smooth and efficient loading and shipping process for our high-quality Veneer Dryer Machines, guaranteeing safe and timely delivery to customers worldwide.