28m Four Deck Natural Gas Veneer Dryer Shine Veneer Dryer GTH30-28

Shine Birch Veneer Roller Dryer: Precision-Engineered for Efficient, Low-Cost Drying

In the competitive birch veneer processing industry, maximizing efficiency while maintaining consistent quality is critical. Shine Machinery’s roller veneer dryer stands out as a professional-grade solution, designed to meet the unique demands of birch veneer drying with precision, energy efficiency, and reliability.

1. Hourly output: 3.5m3

2. Heating Section: 24m

3. Final Moisture: ≤10%

4. Heat Source: Natural Gas

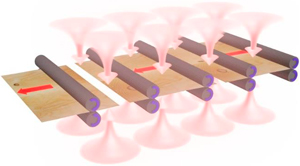

Dimensional Design: Optimized for High Throughput & Uniform Drying

The dryer’s 3000mm working width sets the stage for high-capacity processing, allowing simultaneous handling of multiple birch veneer sheets. Paired with a 2400mm heating zone and 4000mm cooling zone, the machine ensures gradual, uniform heat transfer—critical for avoiding warping or cracking in thin (0.8–8mm) or thick (up to 8mm) birch veneers. This extended heating-cooling structure eliminates “hot spots” and ensures every sheet exits with consistent moisture content (≤10% final, down from 80% initial), a hallmark of premium birch veneer quality.

Natural Gas Heating: Efficient, Eco-Friendly, and Cost-Effective

Powered by a natural gas heat carrier, this dryer leverages clean, abundant energy to reduce operational costs and environmental impact. Natural gas combustion delivers rapid, stable heating with minimal emissions, making it ideal for regions with reliable gas infrastructure. Compared to electric or biomass alternatives, it offers:

Lower Fuel Costs: Natural gas is often cheaper than electricity or biomass in many markets, reducing long-term operational expenses, such as in Russia, Hainan etc.

Faster Heating Response: The high thermal conductivity of natural gas ensures quick temperature stabilization, shortening drying cycles and boosting throughput.

Specifications

| Model | GTH30-28/4 |

| Veneer thickness, mm | 0,8 - 8 |

| Initial humidity, % | 80 |

| Final moisture, % | ≤10 |

| Temperature in the dryer, ℃ | 140 - 180 |

| Roller length, mm | 3 200 |

| Working width, mm | 3 000 |

| Number of floors | 4 |

| Heating zones, mm | 24 000 |

| Cooling zone, mm | 4 000 |

| Feed speed, m/min | 5 - 22 |

| Productivity, m3/hour | 3,5 |

| Conveyor power, kW | 22 (5.5 x 4 pcs.) |

| Heating fan power, kW | 96(4 x 2pcs x 12 sections) |

| Cooling fan power, kW | 16(4 x 4pcs) |

| Power-boiler of natural gas, kW | 7.5 |

| Total power, kW | 141,5 |

| Electricity consumption on average per hour, kW | 92 |

| natural gas burner | 2.4 million kcal |

| Gas consumption, m3/hour. | ≈120 |

| Number of personnel, people/cm | 4 |

| Overall dimensions, mm | 39 000*5 000*3 500 |

| Weight, kg | ≈100 000 |

Performance Metrics: Speed, Consistency, and Reliability

Productivity: With a 3.5 m³/hour drying capacity, the machine processes 28–30 m³ of birch veneer daily (under standard 8-hour shifts), meeting the demands of medium to large-scale furniture, flooring, or decorative woodworking facilities.

Feed Speed Flexibility: Adjustable from 5–22m/min, the conveyor system adapts to varying veneer thicknesses and moisture levels, ensuring no material waste and seamless integration with upstream/downstream processes.

Power Efficiency: A total power consumption of 141.5 balances performance with energy savings, critical for manufacturers prioritizing sustainability without compromising output.

Automatic loader for dryer & Semi-automatic collector for dryer

Shine Machinery's independently developed automatic sheet feeding system is specifically designed for veneer drying production lines, achieving full automation from sheet laying to drying, significantly improving production efficiency and reducing labor costs. The system is compatible with various types of veneer dryers and is particularly suitable for large-scale continuous production on roller veneer dryer lines.

Processing scheme

Shine Machinery's innovative hot air circulation system is a core component that ensures uniform drying of veneer and energy efficiency. The system is specifically designed for veneer dryers, utilizing scientific air duct layout and intelligent control to maximize thermal efficiency. It is suitable for high-quality drying of veneer with thicknesses ranging from 0.5 to 8 mm.

Packing and Transportation

For 4 decks 28m Gas veneer dryer

Office building and production workshop.

Thermal efficiency optimization – Uses high-temperature heat pumps or steam heat exchange systems, which are 30%–50% more energy efficient than traditional dryers.

Intelligent temperature control – Equipped with a PLC automatic control system that accurately regulates temperature and humidity to avoid energy waste.

Low failure rate – Uses high-quality components such as imported bearings and high-temperature resistant motors to reduce downtime for maintenance.

Customer visit in Shine Factory

Shine's dryer completely exceeded our expectations! Not only did it solve the problem of uneven drying, but it also achieved significant energy savings. Their engineers also provided detailed operational training after installation, demonstrating a high level of professionalism.