6 Deck Roller Veneer Dryer Machine

6-Deck Design Delivers Industrial-Scale Capacity

Shine’s 6-deck veneer dryer (42m in length, 6m in working width) is built for large-scale production. For plywood producers, this means unmatched throughput: with a daily output of 15–18m³ per hour, it cuts drying cycles by 40% compared to traditional 2 or 4-deck models.

Whether drying thin decorative veneers for furniture or thick blanks for construction plywood, this dryer ensures consistent, high-quality results at industrial scale.

Product Introduction of 6 Deck Roller Veneer Dryer Machine

6 deck roller veneer dryer machine is one of the most crucial phases of veneer production. The main objective of the drying process is to produce high-quality optimally dried veneer sheets with the highest possible efficiency. This is carried out by removing water from the sheet and decreasing moisture content to an optimized level by using hot and humid air inside a dryer. By choosing industrial veneer drying, you improve veneer quality with uniform drying result. As a result, you get high-quality. Its robust and sturdy structure guarantees a long lifetime and steady production with high efficiency. The proven technology gives you advanced production efficiency and capacity.

6 Deck Roller Veneer Dryer Machine

Advantages of 6 Deck Roller Veneer Dryer Machine

1. The biomass burner, a patented product independently developed by our company, can directly use crushed wood waste as fuel to provide a heat source for the dryer, which is energy-saving and environmentally friendly, and greatly reduces the drying cost.

2. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

3. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

4. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

5. After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

6. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

7. We have a professional R&D team which can design different models according to customer’s special requirement.

8. The perfect after-sale service team can supply 24 hours online service.

Video

6 Deck Roller Veneer Dryer Machine

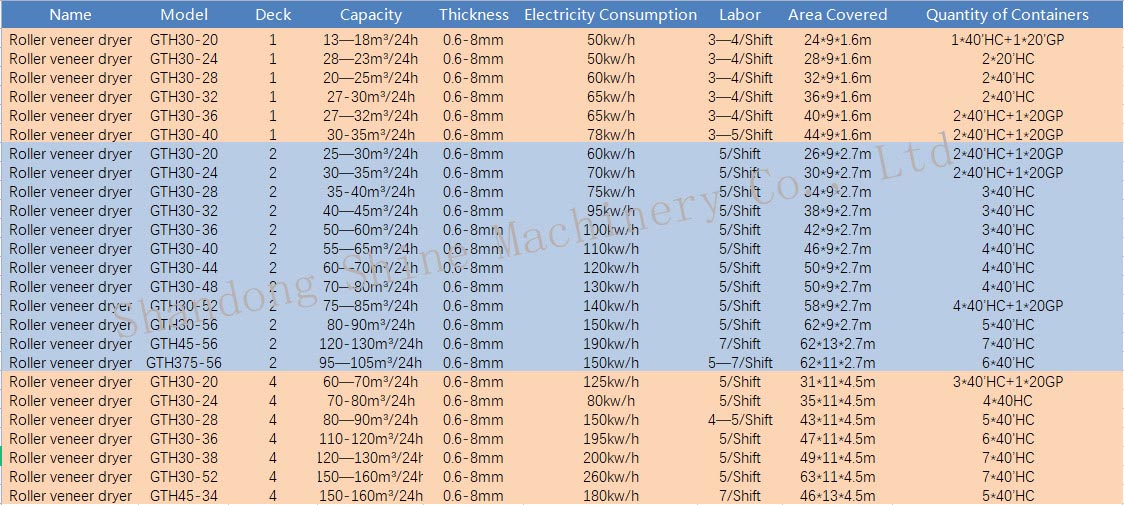

Product Parameters of Roller Veneer Dryer Machine

Exhibition and Customer Case

Customers from all over the world visit

Product Packaging And Transportation