3 Deck 40m Plywood Veneer Dryer Machine

3 deck 40 m plywood veneer dryer machine has features of high productivity,energy saving and environmental protection.The drying capacity is improved greatly by using the continuous 3deck veneer dryers.

Veneer thickness: 0.6-8mm

Drying capacity (m³/day): 90-95cbm

Actual electricity consumption: About 130kwh per hour

Product Introduction of 3 Deck 40m Plywood Veneer Dryer Machine

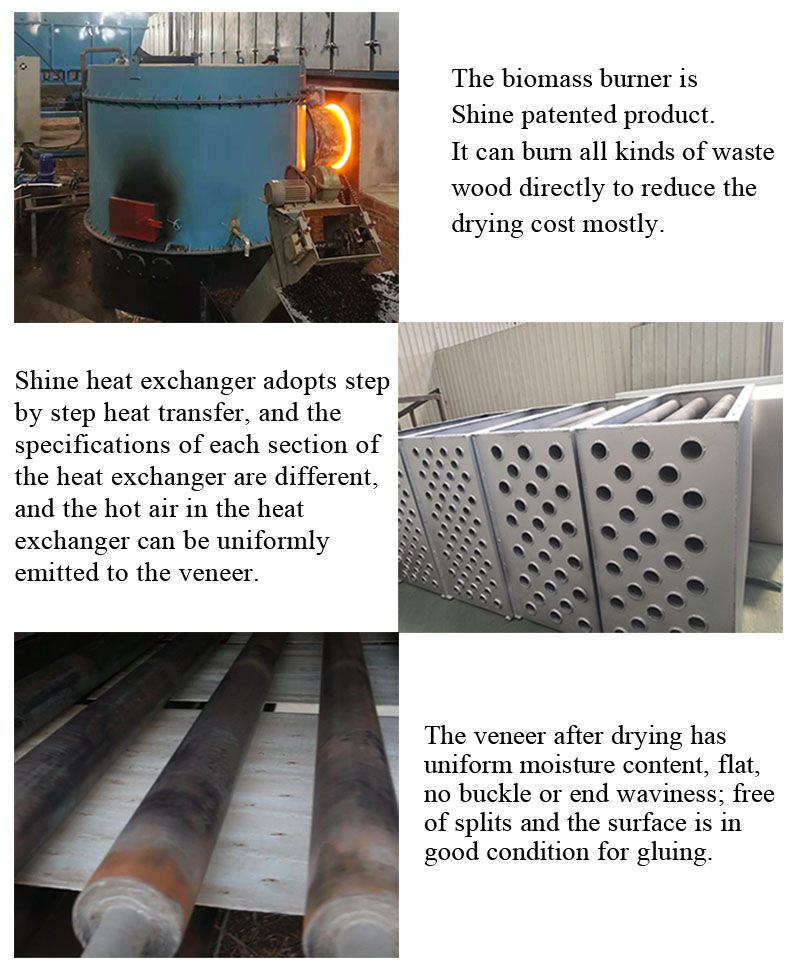

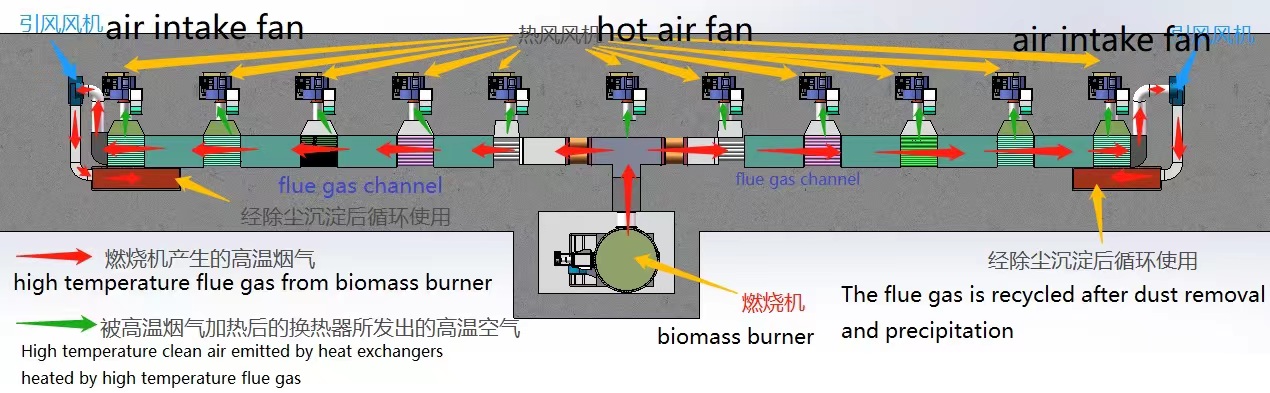

The 3 deck 40m plywood veneer dryer machine is heated by Biomass Burner and has the drying capacity of 4 m3/ h.Shine veneer roller dryer is designed to ensure the maximum quality and productivity and highest possible energy efficiency for both furniture and plywood veneer manufacturing.The 3 deck dryer has the higher drying capacity compared to the 1 and 2 deck dryer while pricing is more favorable at the same time compared to 4 deck veneer dryer.Utilizing the biomass burner as the heat source,the total production cost(labor,fuel and electrictiy power) is only USD6-USD12 per cubic meter.

plywood veneer dryer machine in Thailand

3 deck plywood veneer dryer machine

plywood veneer dryer machine in Myanmar Customer's Factory

Advantages of 3 Deck 40m Plywood Veneer Dryer Machine

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform,and the high temperature drum has direct contact with the wet veneer for heat transfer,and the heat efficiency is high,the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, less ancillary equipment,convenient for transportation,quick installation,and can be put into use quickly and conveniently.

4.Standardized production models,can make different sections or decks according to different capacity requirements,which can meet different customers' requirements.

5.Each section with heat exchanger,which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark,which can reduce the fuel cost greatly for the user.

Video

3 Deck 40m Plywood Veneer Dryer Machine

Product Parameters of 3 Deck 40m Plywood Veneer Dryer Machine

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 90-95cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:11KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 11KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 185.5KW |

Actual electricity consumption | About 130kwh per hour |

Product Details

Our Factory

Our Certificate

FAQ

Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machines by ourselves.

Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 50 countries customer.