Jet Roller Veneer Dryer

This dryer is renowned for its simple operation, featuring an intuitive control system that allows for easy setup and monitoring, reducing the potential for operator error. Its design incorporates numerous safety and practicality features, ensuring a secure working environment while facilitating straightforward daily use. The machinery is engineered for exceptionally stable operation, with a robust construction that minimizes vibration and noise, leading to consistent performance over extended periods. Furthermore, it is designed with easy maintenance in mind; easily accessible components and a simple mechanical structure significantly reduce downtime and associated upkeep costs.

The jet roller veneer dryer was equipped with an automatic feeder device that can feed the veneer to the dryer and save labor costs. The veneer after drying has uniform moisture content, and it is flat without buckles or end waviness. Less maintenance is required for the Shine veneer dryer machine, and no veneer jamming leads to less downtime. Shine biomass veneer dryers can reach the user's special requirements and achieve an ideal drying effect.

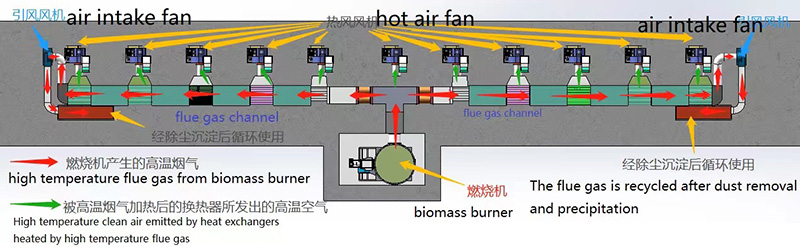

The working principle is that the veneer is clamped by the upper and lower seamless steel tube rollers, and the oven temperature reaches 140 ℃ by preheating, and then enters between the upper and lower rollers and blows high-pressure hot air to the upper and lower sides of the veneer through the hot air pipe for rapid drying. So it can make the veneer smooth and moisture content even after drying, and it also has the characteristics of direct contact heat transfer between the high-temperature roller and the wet veneer, high thermal efficiency, low heat loss, and reducing heat energy consumption.

Product Parameters of Jet Roller Veneer Dryer

Model No | GTH30-52 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 48m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 6.7 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(48pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10-ton biomass burner | Power: 16.5KW |

Total power | 284.5KW |

Actual electricity consumption | About 200kwh per hour |

Overall Dimension(L*W*H) | 63m×11m×3.5m |

Project Case

In the wood processing industry, selecting an efficient and stable dryer is key to ensuring product quality and boosting production efficiency. True confidence stems not from flowery rhetoric, but from the solid validation of countless successful cases. Shine Machinery, with decades of industry expertise, has deployed its four-layer/six-layer wood veneer dryers across the nation and into overseas markets. With numerous on-site installations and widespread customer acclaim, this is the foundation of our bold commitment!

Customer Visiting

Direct Access to Production Lines: Witness military-grade quality control throughout the entire process—from sheet cutting, welding, and assembly to testing.

Observe Equipment in Action: Watch dryers start up live, experiencing firsthand their temperature and humidity precision, energy consumption data, and noise control.

Compare Raw Materials and Finished Products: Randomly sample veneers before and after drying, with moisture content tested on-site—results are immediately apparent!

Packaging & Shipping

Shine understands that the value of high-quality equipment lies not only in its outstanding performance but also in its safe and efficient delivery to your hands. We have established a standardized packing and shipping system, integrating a nationwide logistics network to ensure every four-layer dryer is fully controlled and arrives intact from the factory to the installation site!