High-Temperature Hot Air Circulation Veneer Drying Machine

Shine’s wood veneer dryer is more than a machine—it’s a partner in profitability. With its energy-efficient axial fans, unique heating options, empowering clients to reduce costs, enhance productivity, and deliver high-quality veneers that meet global standards.

1.Customizable (customized one-stop service)

2. Professional factory production

3.The roller uses a φ89mm special shaft tube, which is corrosion-resistant and rust-proof

4.Flexible local support (technology and maintenance)

5. Stable equipment and low failure rate

6.Highly automated and efficient (fully automatic veneer feeding and receiving system)

The roller veneer drying machine is a new generation of wood veneer drying equipment. It uses the latest international pressurized contact veneer drying technology. It has the advantages of simple operation, safety and practicality, stable operation, easy maintenance, hot pressing-leveling-drying in one step. The recycling of hot air greatly reduces the operating costs of enterprises, improves the quality of veneers, and increases production.

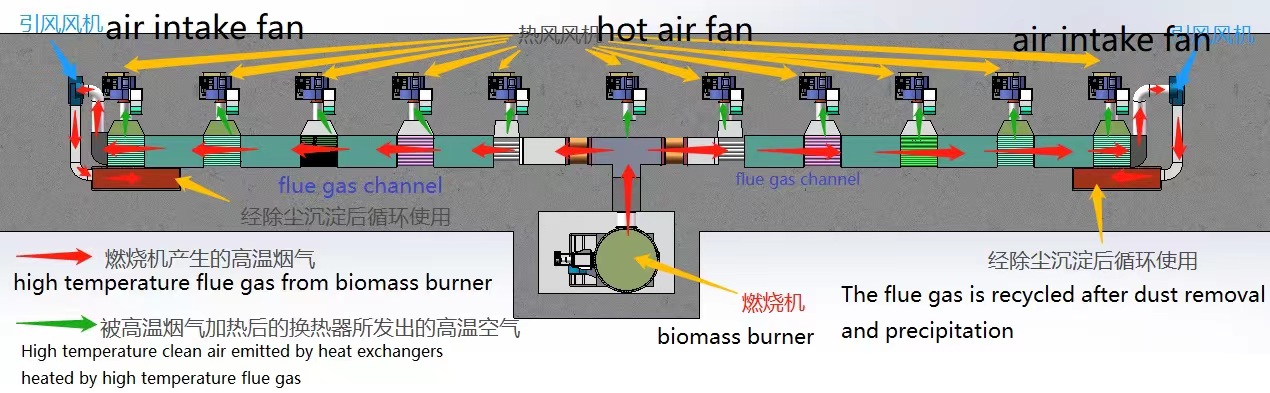

Energy Savings Through Hot Air Recycling

Wasting energy is costly. That’s why Shine’s dryer features a well-developed heat exchange system that recycles hot air. By reusing heat that would otherwise escape, the machine slashes unnecessary energy waste, lowering your operational costs significantly. This efficiency doesn’t just save money—it also reduces your carbon footprint, making it a sustainable choice for eco-conscious businesses.

The dried veneer is flat and has a relatively uniform moisture content. When the veneer is located between two sets of rollers, it can shrink freely in the horizontal direction, reducing the generation of cracks and having good drying quality. The heat dissipation process is carried out in a flat state. In the benign physical process of wood shrinkage, the veneer does not warp or deform, the breakage rate is low, and the yield rate is high.

Smart Automation: Simple Operation, Low Maintenance

Running a busy workshop means minimizing downtime. Shine’s dryer is built with automatic temperature control and speed regulation systems in the control cabinet. This smart tech lets you precisely set and monitor the final moisture content of your veneers—no guesswork required. Even better, the system is designed for low failure rates, so you spend less time fixing issues and more time producing.

Product Parameters of Veneer Drying Machine

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Customer Case

The Factory

Shine specializes in the dryer manufacturing since 1999, is the first Chinese factory who produce 6 deck roller veneer dryer.

Packaging & Shipping