plywood veneer roller dryer

Our roller veneer dryer is manufactured through professional factory production, ensuring each unit meets the highest industrial standards. A key feature of this veneer drying system is its use of a φ89mm special shaft tube in the rollers, which is corrosion-resistant and rust-proof, significantly enhancing durability in high-humidity environments. This robust construction contributes to exceptionally stable equipment performance and a low failure rate, maximizing uptime and productivity. The efficiency of this roller veneer dryer is demonstrated by a veneer drying output that is 2–3 times greater than that of original traditional dryers. Furthermore, the dried veneer is consistently flat and wrinkle-free, ensuring superior product quality. Proven in global operations, our dryer has been exported to Europe, South America, Asia, Africa, and other regions, with performance data and operational status available for real-time viewing by interested clients.

Introducing our cutting-edge Veneer Dryer, engineered for high efficiency and precision in drying veneer sheets. Equipped with an automatic temperature control and speed regulation system, this dryer adjusts to the thickness and moisture content requirements of your veneer, ensuring optimal results every time. Its step-by-step heat exchange system and energy-saving design make it an indispensable asset for any veneer production line. The reliable roller conveyance system guarantees continuous operation without jams, boosting productivity and reducing downtime.

Advantages of the veneer dryer

The hot air fan and cold air fan of the dryer adopt the latest axial flow fan, which reduces power consumption and greatly reduces the power of the whole machine, which can further reduce the later operation cost.

The Shine heat exchanger adopts step-by-step heat exchange. The specifications of each heat exchanger are different, and the hot air inside can be evenly distributed to the single board. After drying, the moisture content of the veneer is uniform, smooth, without wrinkles or end ripples, without cracks, and the surface is in a good glued state.

The roller veneer dryer adopts frequency conversion speed regulation, which can adjust the feeding speed according to your veneer thickness and moisture content, so as to achieve the ideal drying effect.

The fuel source can be waste wood or bark after peeling, which can greatly reduce fuel costs for users.

Perfect after-sales service system, 24-hour online service, remote operation, so that customers can rest assured after installation. Regular follow-up services for old customers, sufficient and timely supply of spare parts.

Product Parameters of Veneer Roller Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | 2-deck veneer dryer | |||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Exhibition and Customer Visiting

Shine has always believed that great equipment stems not only from manufacturing but also from communication. Whether you're currently facing challenges with drying uniformity, excessive energy consumption, or automation integration, we welcome you to engage in in-depth discussions with us during the exhibition. Together, let's advance drying technology.

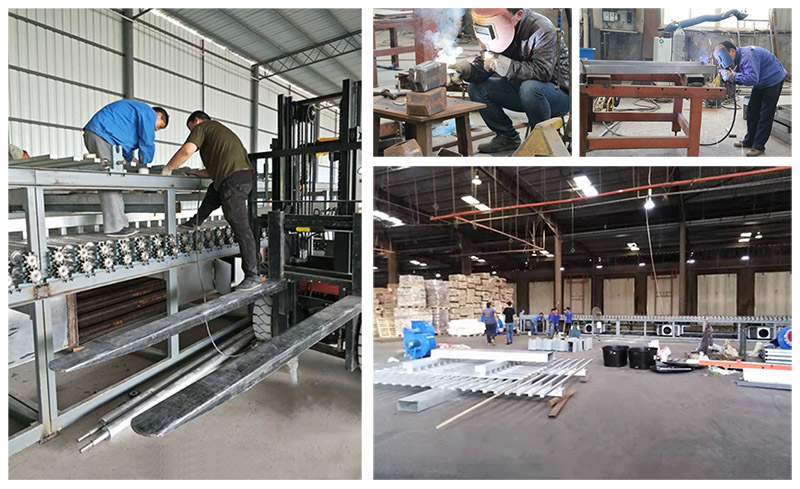

The Factory

Shine Machinery operates its own large-scale modern manufacturing base, covering a vast area and integrating R&D, production, and testing. The factory features scientifically zoned areas, including a CNC cutting center, structural welding workshop, machining workshop, automated assembly line, spray painting and baking line, and a complete machine testing platform—encompassing the entire production process. The production line combines modular and assembly-line approaches, ensuring standardized production and flexible customization proceed seamlessly.

The installation

Shine Machinery has established a comprehensive international installation, commissioning, and technical service system to ensure the smooth startup and long-term stable operation of equipment for overseas customers.

Packaging & Shipping

The machine is first wrapped in anti-rust film and waterproof material. Critical components such as the control cabinet, motors, and sensors are disassembled (when necessary) and packed separately in shock-absorbent boxes with foam and reinforced padding.