4 Deck Roller Veneer Dryer Heat with Thermal Oil

The 4 Deck Roller Veneer Dryer Heat with Thermal Oil has high veneer drying productivity with high drying temperature, saving labor cost with the automatic feeder, energy efficiency, and environment friendly.

With the thermal oil running inside the radiators in the roller veneer dryer, the heating temperature is controlled accurately to get a more uniform veneer drying effect.

A Thermic oil veneer dryer can obtain a high operating temperature at low pressure and can do high precision control on the drying temperature.

Product Description of 4 Deck Roller Veneer Dryer

4 Deck Roller Veneer Dryer Heat with Thermal Oil is famous for continuously making high quality veneer with a uniform moisture content, and an esthetical appearance. Shine veneer dryers features the highest efficiency while using the minimum amount of thermal energy.

The 4 Deck veneer roller dryer heat with thermal oil has a standard working width of 3000mm and a customized working width of 4500mm in order to meet the requirement of the large drying capacity by the customer. The standard heating chamber of the 4 Deck Roller Veneer Dryer is 2 meters as a heating section and 2 meters as a cooling section. With the thermal oil running inside the radiators in the roller veneer dryer, the heating temperature is controlled accurately to get a more uniform veneer drying effect before gluing into plywood.

4 Deck Roller Veneer Dryer in Latvia

Features of the 4 Deck Roller Veneer Dryer Heat with Thermal Oil

1. Oil veneer dryer is one of the traditional veneer dryer types.

2. The drying temperature is higher than steam veneer dryer, more precise temperature control for better uniform moisture content.

3. The veneer surface is flat and smooth with uniform moisture content after drying with thermic oil fluid roller veneer dryer.

4. Thermic oil veneer dryer can obtain a high operating temperature at low pressure and can do high precision control on the drying temperature.

5. The dried veneer quality is high which can be used as the raw material for the high-end plywood product.

6. The composite drying cost using steam is less than the thermal oil heating veneer dryer machine.

7. Thermal oil type veneer dryer is safe and efficient way to run the veneer dryers.

Video of the 4 Deck Roller Veneer Dryer Heat with Thermal Oil

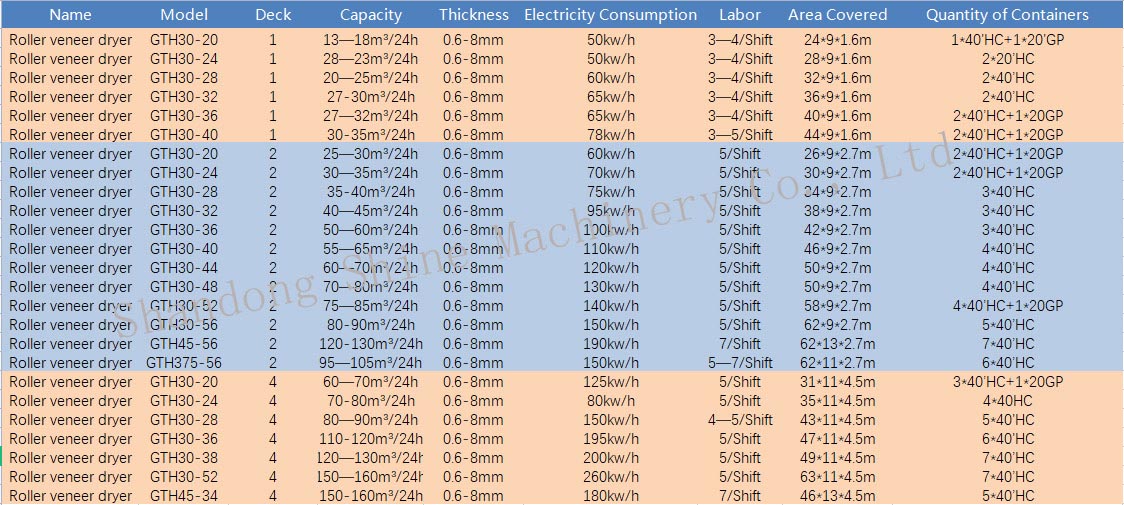

Technical Parameters of the 4 Deck Roller Veneer Dryer

Quality Certificates of Shine Veneer Dryers

Parts of Veneer Dryer

Factory and Workshop

We are very welcome to visit the site and our factory