Advantages for Using a Biomass Burner as the Heat Source for Veneer Dryers?

In the competitive wood veneer processing industry, optimizing veneer drying capacity while minimizing operational costs is a top priority for manufacturers. As traditional heat sources like steam boilers and thermal oil systems face rising expenses and safety concerns, many are turning to an innovative solution: biomass burners. At Shine Machinery, our biomass burner technology has redefined efficiency in veneer dryer operations, offering unmatched advantages that drive both productivity and profitability. Here’s why it’s becoming the industry’s go-to choice.

1. Lower Initial Investment & Enhanced Safety

Traditional heat sources such as steam or thermal oil systems often require expensive pressure vessels, complex installations, and rigorous maintenance—adding significant upfront costs. In contrast, Shine’s biomass burner operates without pressure vessels, drastically reducing initial investment and simplifying installation. Its robust, non-pressurized design also minimizes safety risks, making it a safer, more stable choice for continuous industrial use. For manufacturers, this means faster ROI and peace of mind.

2. Zero Heat Loss: Direct Air Heating for Maximum Efficiency

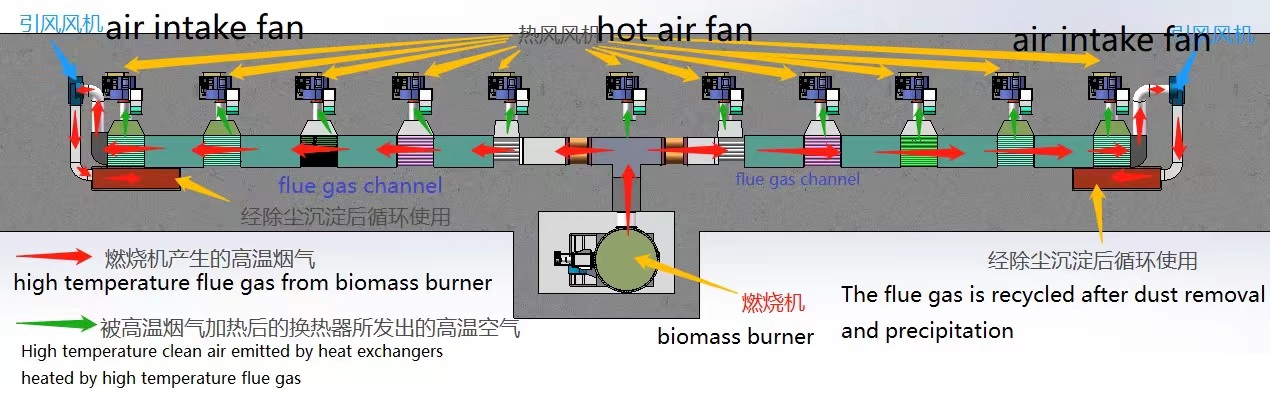

One of the most critical advantages of Shine’s biomass burner lies in its superior heat exchange efficiency. Unlike traditional systems that rely on “two-step” heat transfer (e.g., heating water for steam or oil for thermal fluid, then transferring heat to air), our burner directly heats the air in the veneer dryer. This “single-step” process eliminates intermediate energy losses, ensuring nearly 100% of the fuel’s energy is used to dry veneer sheets. The result? Faster drying cycles, higher throughput, and reduced energy waste.

3. High-Temperature Performance: Boosting Veneer Drying Capacity

Efficient drying isn’t just about speed—it’s about consistency. Shine’s biomass burner achieves internal dryer temperatures of up to 200°C, a critical threshold for accelerating moisture evaporation in veneer sheets. This high heat output ensures uniform drying across all sheets, preventing bottlenecks in production lines and maximizing the veneer drying capacity of your facility. For manufacturers processing large volumes of wood veneer, this translates to shorter lead times and increased output.

4. Waste-to-Energy Innovation: Lower Fuel Costs & Reduced Waste

Shine’s biomass burner doesn’t just save money—it transforms waste into value. In typical veneer production, byproducts like bark, offcuts, and waste wood from rounding or rotary peeling machines are often discarded, accumulating as waste and incurring disposal costs. Our system allows these materials to be crushed and burned directly as fuel, eliminating waste pileup and converting scrap into energy. This not only reduces fuel expenses but also aligns with sustainable manufacturing practices, appealing to eco-conscious clients and regulators.

Why Choose Shine Machinery for Biomass Burner Solutions?

At Shine Machinery, we combine cutting-edge engineering with deep industry expertise to deliver solutions that work. Our biomass burners are rigorously tested for durability, efficiency, and compatibility with veneer dryers of all sizes—from small-scale workshops to large industrial lines. With thousands of installations worldwide, we’ve proven that our technology delivers measurable results: lower costs, higher yields, and a smaller environmental footprint.

In an era where operational efficiency and sustainability are non-negotiable, Shine Machinery’s biomass burner stands out as a game-changer for veneer drying. By addressing the limitations of traditional heat sources—cost, inefficiency, and waste—our technology empowers manufacturers to thrive in competitive markets.

Ready to upgrade your veneer dryer with a smarter, more cost-effective heat source? Contact Shine Machinery today to learn how our biomass burner can transform your production line.

Shine Machinery: Powering Veneer Production with Innovation!