Steam Heated Veneer Dryer

Steam Heated Veneer Dryer is the latest generation of veneer drying equipment,using the latest international pressure contact veneer drying technology,with the advantages of simple operation,safety and practicality,and stable operation. Exhaust gases from plywood factories can be used as a heat source.The dryer can be equipped with a steam pipe. Steam is stable and clean as an energy source.

Advantage of Steam Heated Veneer Dryer

Steam heated veneer dryer adopts intelligent technology,the moisture content of the dried veneer is uniform,flat,without wrinkles and cracks.Shine dryer adopts frequency conversion control,which can automatically adjust the transmission speed and temperature according to different veneer thickness and moisture content,so as to achieve the ideal drying effect. And the failure rate is low,the single board is less blocked,and the downtime can be reduced.The temperature control of the steam dryer is more precise,and the temperature can be controlled up to 0.1 degrees Celsius.The temperature control of the steam dryer is more precise,and the temperature can be controlled up to 0.1 degrees Celsius.

1 Deck Steam Heated Veneer Dryer

Steam Heated Veneer Dryer in Customer's Factory

Main Features of Steam Heated Veneer Dryer

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The Steam Heated Veneer Dryer adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect .

3.Shine core veneer dryer or face veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5.Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark ,which can reduce the fuel cost greatly for the user.

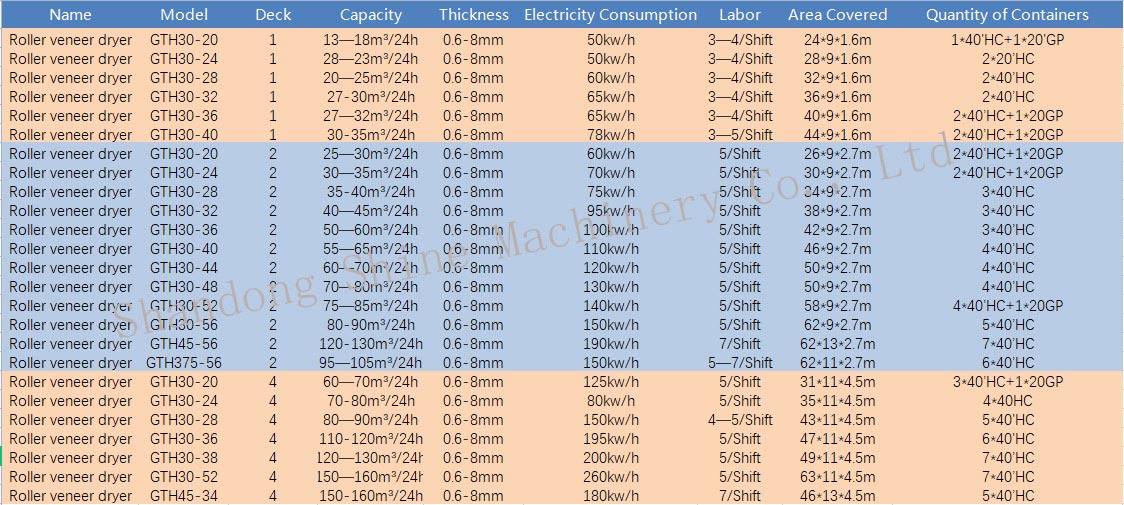

Product Parameters of Steam Heated Veneer Dryer

Our factory

We has 10 standardized workshops, covering an area of 7000 squre meter and has a building area of 12,000 square meters. We has 150 sets of various equipments and has complete machining, heat treatment, punhching, welding and six production lines.

Our Certificate

Transportation

We offer several ways of transportation, we ship the main part of veneer dryer by sea freight and parts by air freight.