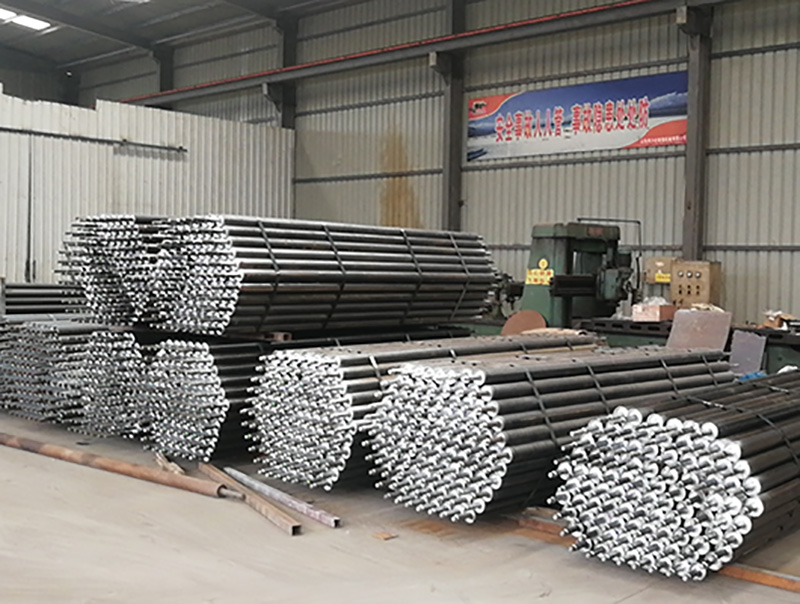

Rollers for Veneer Dryer Parts

Roller Material: carbon steel Q235B, Special shaft tube, Stainless steel or customized material in line with the customers' requirement.

Roller Diameter: 89mm, 102mm.

Roller Distance: 180mm, 330mm.

Roller Length: 3000mm, 3750mm, 4500mm, 6000mm.

The Critical Role of Rollers in Modern Veneer Drying Systems

In the realm of wood processing technology, roller veneer dryers represent a significant advancement in efficiency and quality output. As the name implies, the system's core components are the rollers for veneer dryer applications, which are fundamental to the machine's operation and the superior quality of the final product. These precision-engineered rollers perform distinct, critical functions that directly impact the flatness, integrity, and overall quality of the dried veneer.

The importance of these rollers for veneer dryer systems cannot be overstated, particularly in roller veneer dryers designed for high-volume, continuous production. Within these industrial wood veneer dryers, two primary sets of rollers work in synchronized harmony: the upper rollers and the lower driven rollers.

The upper rollers act as a constant, gentle pressing mechanism. Utilizing their own weight, they apply consistent downward pressure on the veneer sheet as it travels through the drying chamber. This crucial function serves multiple purposes:

Eliminating End Waviness: It suppresses the natural tendency of thin wood veneer to warp or develop wavy edges during the intense heating process.

Preventing Cracking: Holding the veneer flat prevents the introduction of stresses that lead to checking and cracking, ensuring a flawless surface.

Achieving Perfect Flatness: The continuous pressure ensures the finished veneer emerges exceptionally flat and dimensionally stable, which is paramount for subsequent lamination and finishing processes.

Conversely, the lower rollers are the dynamic heart of the conveyor system. They are positively driven by a robust arrangement of chains and gears, providing the motive force that carefully transports the veneer from the infeed to the outfeed end of the core veneer dryer. Their synchronized rotation guarantees a smooth, consistent, and jerk-free forward movement, which is essential for uniform drying.

The operational process of these roller veneer dryers is a marvel of industrial engineering. The journey begins when planer-cut or rotary-cut veneer is fed into the inlet of the jet roller-type veneer dryer. Inside the machine, the veneer is gently grasped and propelled forward by the relative rotation of numerous pairs of these upper and lower rollers for the veneer dryer.

As the veneer sheet travels on its predetermined path through the various stages of the wood veneer drying machine, it is subjected to a highly controlled drying environment. Located between the pairs of rollers are powerful nozzles that blast hot air at temperatures between 140° and 200° Celsius directly onto the top and bottom surfaces of the veneer. This high-velocity jet (with a wind speed of approximately 15 m/s) ensures rapid and efficient heat transfer, violently stripping away moisture without damaging the wood fibers.

The entire process is governed by a sophisticated electronic control system integral to the core veneer dryer. This system intelligently adjusts the rotational speed of the driven rollers for the veneer dryer, thereby controlling the veneer's residence time inside the heated chamber. By optimizing this travel speed based on veneer species, initial moisture content, and thickness, the system guarantees that the optimal drying effect is achieved for every batch.

A final, notable benefit of the mechanical action in roller veneer dryers is an inherent ironing effect. As the veneer passes under the weighted upper rollers, any minor unevenness or imperfections are smoothed out. This supplementary process ensures that the veneer produced is not only perfectly dry but also possesses a superior surface quality, ready for immediate use in high-value manufacturing such as furniture, cabinetry, and architectural panels. This combination of precise mechanical control and aggressive jet-drying makes roller-type veneer dryers an indispensable asset in modern veneer production.