High efficiency veneer drying machine

As a leading manufacturer of veneer drying machines, Shine Machinery specializes in producing premium Core Veneer Dryers and Wood Veneer Making Machines, offering comprehensive ODM/OEM support to meet your specific production requirements. Our professional factory production ensures every machine is built with precision engineering and strict quality control, delivering 2-3 times higher output compared to traditional dryers.

Shine Machinery - Your Trusted Partner for High-Efficiency Veneer Drying Solutions

The roller veneer dryer adopts advanced drying technology and an intelligent control system to ensure that each piece of veneer can be dried in the best condition. Regardless of the type of wood, our equipment can effectively remove excess moisture, improve the strength and stability of the veneer, and prevent cracking and deformation. With the deepening of environmental protection concepts, energy saving and consumption reduction have become an important trend in the development of the industry. Our veneer dryer is designed with full consideration of energy efficiency, low energy consumption, and minimizes production costs, bringing you higher economic benefits.

We provide customized services and tailor drying solutions according to the specific needs of customers to ensure that the configuration of the equipment is perfectly matched with your production line. Our technical team will accompany you throughout the process, provide installation, commissioning, and subsequent maintenance services, so that you have no worries during use. Choose our veneer dryer, and you will experience efficient, energy-saving, and reliable veneer drying solutions, bringing sustainable development momentum to your business.

Product Parameters of Veneer Drying Machine

Wood species | Veneer drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | 2-deck veneer dryer | 4-deck veneer dryer | ||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Exhibition and Customer Visiting

At the recently concluded Shanghai International Woodworking Industry Exhibition (LIGNA Shanghai), Shine Machinery's veneer dryer became the highlight of the event, attracting over 200 professional clients from more than 20 countries, including Russia, Vietnam, Turkey, Brazil, and India, who visited the booth for discussions. We provided customized drying solutions tailored to the specific needs of clients from different countries, offering one-on-one consultations on-site, which earned widespread praise!

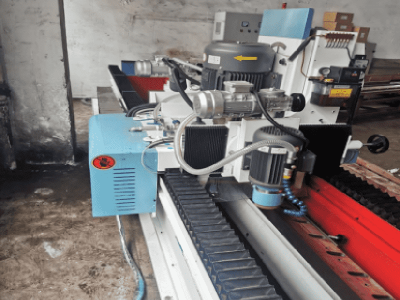

The Factory

✅ Professional R&D team: Over 50 engineers dedicated to wood drying technology, with annual R&D investment exceeding 5% of revenue, continuously optimizing core metrics such as thermal efficiency and automated control.

✅ Patented technology: Hold 12 national invention patents (e.g., high-efficiency hot air circulation system, intelligent humidity control), achieving energy consumption 15-20% lower than industry standards.

✅ Customized Development Capabilities: Equipment parameters (such as temperature curves and conveying speed) can be adjusted according to customer requirements, accommodating the characteristics of various single boards such as eucalyptus, poplar, and pine.

Packaging & Shipping

Main frame: Anti-rust oil + waterproof film + steel frame fixing are used to prevent corrosion in humid marine transport environments.

Hot air system/electrical control cabinet: Packed separately in a box, filled with shock-absorbing foam, and supported by wooden frames to prevent damage to precision components during transport.

Conveyor belt/roller: Wrapped in PE protective film and packed in a wooden box, with custom protective sleeves added to key bearing parts.