Energy Saving Roller Veneer Drying

1. Professional Plant Production

2. Fully Customizable Solutions

3. Reliable Performance & Durability

4. Smart Moisture Monitoring

5. Quick & Easy Installation

6. Premium Materials for Long Term Using

Energy Saving Roller Veneer Drying

In the modern wood veneer processing industry, the drying quality of veneer directly affects the quality and service life of the finished product(plywood). Our veneer dryers stand out for their efficiency, energy saving and excellent drying results. Using advanced hot air circulation technology, this wood veneer dryer equipment can not only quickly remove moisture from the wood veneer in a short time, but also maintain the natural texture and color of the wood veneer. Furthermore, it ensures the perfect quality of the finished plywood product. At the same time, its unique energy-saving design significantly reduces power consumption and saves operating costs for veneer making factories, plywood making plants. It is the best choice for pursuing efficient production and environmental protection concepts.

Advantages of Roller Veneer Drying

1. Uniform and Consistent Drying

The roller veneer dryer has the premium hot air ciculation system and can guarantee the hot air is even to the surface and back of the veneer. After drying , the moisture content is uniforma dn consistent.

2. High Efficiency with Energy Savings

Advanced heat recovery and optimized airflow design significantly reduce energy consumption while maintaining high drying speed.

3. Precision Moisture Control

Real-time moisture sensors monitor the moisture content levels inside the roller dryer machine. It improves the veneer drying quality.

4. Reduced Cracking & Warping

Temperature inside the dryer is controlled between 140 and 180℃ so that the veneer will not be too dry or wet. No cracking or warping occured.

5. Adaptable to Various Veneer Types

Customizable working width of the dryer machine can accomadate various wood species, thicknesses, and sizes.

6. Low Maintenance & High Reliability

Durable construction with wear-resistant rollers and self-cleaning mechanisms ensures long service life with minimal downtime.

7. Smart Automation Integration

Automatic feeder, temperature and moisture monitoring, veneer sorting and grading as well as the auto stacking are all available for Shine veneer dryer.

8. Environmentally Friendly Operation

Reduced emissions and energy waste align with sustainable manufacturing standards.

Application scope

Veneer dryers are widely used in:

Furniture manufacturing industry, especially the production of high-end solid wood furniture;

Wood processing plants, essential in the production process of veneer and plywood;

Construction industry, providing high-quality wood materials to meet various construction needs.

Ideal for: Plywood production, furniture manufacturing, and engineered wood applications requiring high-volume, high-quality dried veneer.

After-sales service

We provide comprehensive after-sales services for each veneer dryer, including installation and commissioning, technical training and regular maintenance, ensuring customers a worry-free experience during use.

Product Parameters of Roller Veneer Drying

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

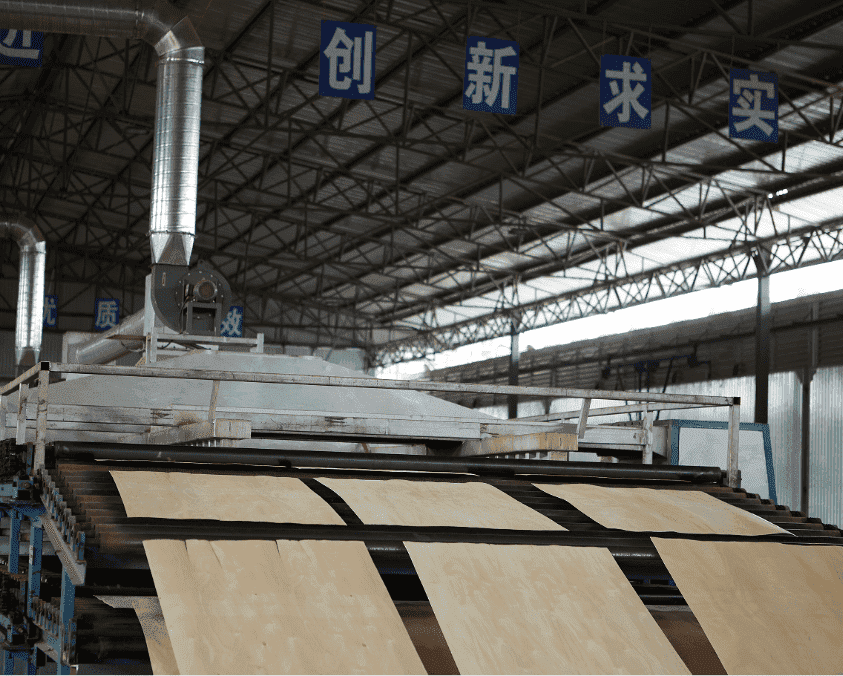

The Factory

Shine Machinery's factory is at Gaotang county, Liaocheng city Shandong China. Welcome to our factory. It is very convenient for customer to get to our factory. You can take a plane to Jinan Airport or take a bullet train to Jinan West Railway Station. And we will pick you up from the airport or railway station. It takes only one hour drive to our factory.

Packaging & Shipping

No mattter it is hot summer or cold winter weather, we guaranteed to load containers as per the agreed time and will not miss the vessel. As always, Shine Machinery treats every customer seriously and serve them from the bottom of our heart.