Core Veneer Dryer

Continuous Core Veneer Roller Dryer Set Machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve an ideal drying effect. The veneer after drying in the Shine veneer dryer is smooth, and the moisture content is uniform. The high-temperature drum has direct contact with the wet veneer for heat transfer, the heat efficiency is high heat loss is small and the heat loss is reduced. The selling price for veneer dried by a roller veneer dryer is higher than natural drying.

Core Veneer Dryer

The core veneer dryer machine made by Shine Machinery is durable in use and has a long service life. All the parts inside the veneer drying machine are good-quality materials that can be guaranteed for long service life. The fuel can be various types of waste wood, waste veneer, and tree bark, among others. The energy consumption is very low, and so the veneer drying cost is significantly reduced compared to the steam or thermal oil type veneer dryer. Shine Machinery is responsible for providing users with the best drying solutions, not just the veneer dryer itself, to ensure higher drying capacity, energy efficiency, and lower fuel cost. In line with the specific production capacity, the wood veneer drying machine can be customized to meet customers' needs.

Product advantages of Core Veneer Dryer:

Improve production efficiency: Efficient drying technology can significantly shorten wood drying time, improve production efficiency, and reduce waiting time.

Save energy costs: The energy-saving and environmentally friendly design reduces energy costs and helps improve your production competitiveness.

Precise control: The adjustable temperature and humidity control system ensures precise control of the drying process, allowing you to produce high-quality wood products.

Reliable and durable: Our veneer dryers undergo strict quality control and have excellent durability, long-term stable operation, and reduced maintenance costs.

Energy saving: Using the latest axial flow fan, the power of the whole machine is reduced by 35%, saving you on electricity bills.

Product Parameters of Core Veneer Dryer

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 70-80cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6-ton biomass burner | Power: 16.5KW |

Total power | 119.5KW |

Actual electricity consumption | About 84kwh per hour |

Covered Space of the whole machine | 50M X 9M X 3M |

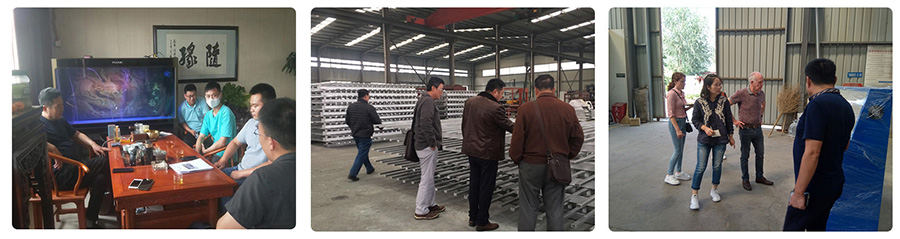

Exhibition and Customer Visiting

For years, Shine Wood Veneer Dryers have earned widespread trust from domestic and international customers through their outstanding performance in stability, efficiency, energy savings, and environmental protection. Our equipment is not only deployed across major timber-producing regions in China but also exported to Southeast Asia, Europe, Latin America, Africa, and beyond, serving hundreds of clients. We empower businesses to enhance quality, boost efficiency, and reduce operational costs.

Factory

Proven Technology, Tailored Solutions: Offers multiple configurations and heat source options, including biomass, steam, and heat pumps, to meet diverse customer needs across all scales;

Significant Energy Savings, Lower Costs: Innovative thermal circulation system and insulation design reduce energy consumption by up to 40% compared to traditional equipment;

Intelligent Control, Hassle-Free Operation: PLC automated control system supports remote monitoring and fault diagnosis, enabling unmanned operation.

Global Service, Rapid Response: Professional technical teams deliver full-cycle support from installation guidance and commissioning training to after-sales maintenance.

Packaging & Shipping

Shine Machinery consistently adheres to a quality management philosophy of high standards and rigorous requirements. Every wood veneer dryer undergoes professional packaging and multiple protective treatments before shipment, fully complying with international export standards. This ensures the equipment arrives safely at global customer sites despite long-distance transportation and complex logistics environments.