Professional Veneer Dryer

1.Professional factory production

2.Customizable (customized one-stop service)

3.Imported accessories, using thicker high-quality steel

4.Stable equipment and low failure rate

5.Highly automated and efficient (fully automatic veneer feeding and receiving system)

6.Flexible local support (technology and maintenance)

Professional Veneer Dryer

The 4 deck veneer dryer adopts an integrated design, which greatly improves the utilization of the floor space. The temperature in the oven is 40-60 degrees Celsius higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180℃, which shortens the total drying time of the veneer, thereby greatly improving the drying output.

The inverter and temperature controller of the traction motor of the veneer roller dryer are connected, which can automatically adjust the transmission speed and temperature of the equipment according to the thickness and moisture content requirements of the veneer, and can accurately control the final moisture content. It avoids the phenomenon that a large number of veneers are over-dried or dried to meet the process requirements.

Advantages of veneer dryer

1、The hot air fan and cold air fan of the dryer adopt the latest axial flow fan, which reduces power consumption and greatly reduces the power of the whole machine, which can further reduce the later operation cost.

2、The Shine heat exchanger adopts step-by-step heat exchange. The specifications of each heat exchanger are different, and the hot air inside can be evenly distributed to the single board. After drying, the moisture content of the veneer is uniform, smooth, without wrinkles or end ripples, without cracks, and the surface is in good glued state.

3、The roller veneer dryer adopts frequency conversion speed regulation, which can adjust the feeding speed according to your veneer thickness and moisture content, so as to achieve the ideal drying effect.

4、The fuel source can be waste wood or bark after peeling, which can greatly reduce fuel costs for users.

5、Perfect after-sales service system, 24-hour online service, remote operation, so that customers can rest assured after installation. Regular follow-up services for old customers, sufficient and timely supply of spare parts.

Product Parameters of Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | 4 deck veneer dryer | |||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Exhibition and Customer Visiting

Shine Machinery is committed to establishing connections with customers through various channels and understanding different customer needs. Each exhibition allows us to have a deeper understanding of the needs and purchasing preferences of customers in different countries and regions for our drying machines. At the exhibition, we can also get in touch with other companies in the same industry, learn about the latest development trends, technological innovation directions, and changes in market demand in the industry.

The installation

Our professional technical guidance team is the core force in ensuring the smooth installation and rapid production of veneer dryers. With solid professional skills and rich practical experience, they provide customers with on-site support throughout the entire process from equipment unloading to commissioning and operation.

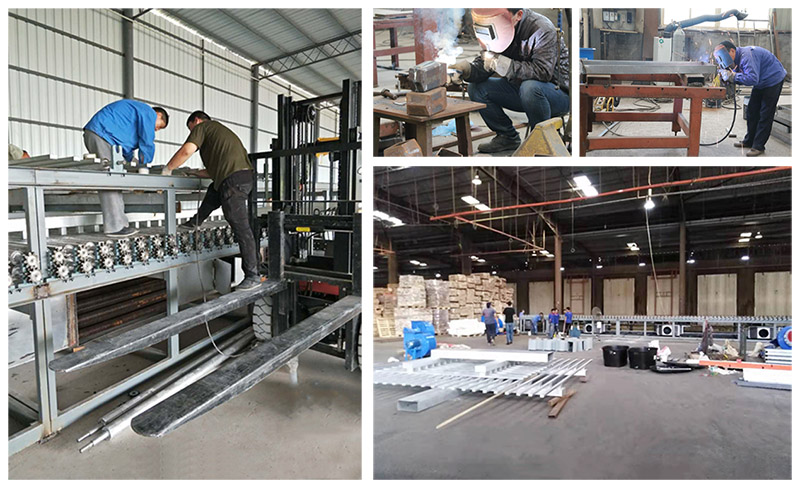

The Factory

Shandong Shine Machinery Co.,Ltd has been engaged in the production of dryer equipment for over 20 years. The industry accumulation over these 20 years is not only a measure of time, but also an accumulation of technical strength and production experience. The company has a professional R&D team and production department. Helping more and more enterprises achieve the transformation of wood processing from extensive production to refined and intelligent production.

Packaging & Shipping

The container loading process is operated by an experienced team and strictly follows international logistics standards. When using professional lifting equipment, anti slip pads will be wrapped around the contact points to prevent scratching of the equipment surface. For the transportation of multiple devices in the same container, a modular fixing method is adopted to firmly connect the equipment to the inner wall of the container through angle steel brackets and fastening straps, while reserving ventilation gaps to avoid the impact of high temperature and high humidity environments on equipment components.