Cost-Effective Veneer Dryer

Designed for maximum efficiency and durability, our Continuous Veneer Dryer Machine offers fully customizable one-stop service, tailored to meet your specific production needs. Manufactured in our professional factory with imported accessories and thicker high-quality steel, this dryer ensures long-term reliability and low comprehensive operating costs, with drying expenses as low as 6-12$/m³.

Shine Machinery's Cost-Effective Veneer Dryer Revolutionizes Wood Core Veneer Drying Efficiency

Our advanced Continuous Veneer Dryer Machine represents a breakthrough in veneer drying technology, delivering substantial energy savings compared to traditional drying methods. This innovative Cost-Effective Veneer Dryer is specifically engineered for wood core veneer drying applications, ensuring exceptional performance while dramatically reducing production costs.

Key advantages of our wood core veneer drying system include

Precision Drying Technology: Guarantees uniform heat distribution across every veneer sheet, eliminating deformation and cracking issues caused by uneven drying

Energy-Saving Design: Features next-generation axial flow fans for both hot and cold air systems, maintaining optimal airflow while reducing total power consumption by over 38%

Production Efficiency: Engineered for continuous operation, our veneer dryer maximizes throughput while minimizing energy waste

Product Parameters of Veneer Dryer

Wood species | Veneer drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | 2-deck veneer dryer | 4-deck veneer dryer | 6-deck veneer dryer | |||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Customer Case

Optional biomass/natural gas/steam multi-heat source solutions, with exhaust emissions compliant with EU 2015/1189 standards.

The waste heat recovery system can reduce energy consumption by 30%, helping customers save on long-term operating costs.

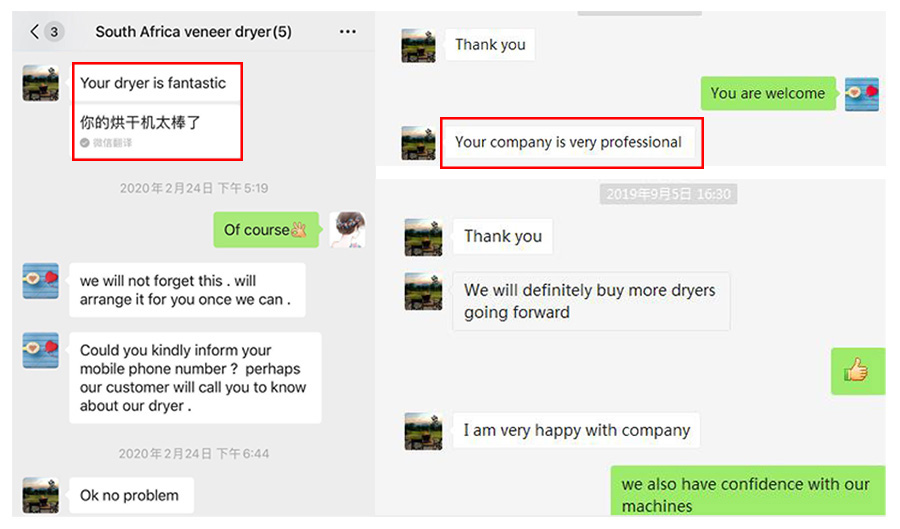

The customer evaluation

✅ 20 years of industry experience – We have designed over 300 customized drying solutions for global clients (e.g., specialized models for ultra-thick wood veneer, models adapted for tropical high-humidity environments, etc.).

✅ Visual confirmation – We provide 3D rendering animations to simulate operational processes, minimizing design errors.

✅ Comprehensive technical support – From interpreting drawings to installation and commissioning, our engineering team offers one-on-one service throughout the entire process.

Our Services

Pre-sale services:

1) Provide a free consultation on all plywood production lines

2) According to the clients' special requirement, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas, install and debug the equipment.

3) Train the first-line operator.

After-sales services:

1) 24-hour online service.

2) Provide the VIDEO on installing and debugging the equipment.

3) Provide technical exchange. Door-to-door service is possible.

The Factory

Shine veneer drying machine has been exported to more than 20 countries and regions, with agents in more than 20 countries. Users can visit the case site nearby.

Packaging & Shipping

We will send professional engineers to your factory to guide the installation and help train your factory workers to operate the equipment. The engineers will not return until the equipment is operating normally.

We are very welcome to visit the site and our factory

Choose us, you need not worry about anything, we will help you arrange all.