Heat Exchanger for Veneer Dryer

Heat Exchanger for Veneer Dryer: The Heartbeat of Efficient, High-Quality Wood Drying

In the world of wood veneer production, consistency, quality, and cost-efficiency are non-negotiable. At the core of every high-performing veneer drying machine lies a critical component that makes these goals achievable: the heat exchanger. This unsung hero of the drying process ensures that heat is transferred efficiently, temperatures are controlled precisely, and energy is utilized optimally—all to deliver flawless, market-ready veneers.

What Does a Heat Exchanger Do in a Veneer Dryer?

A heat exchanger is more than just a technical component; it’s the bridge between raw energy (from sources like biomass, steam, or thermal oil) and the precise, controlled heat needed to dry veneer sheets without compromising their integrity. Its core functions include:

Heat Transfer: Efficiently moving thermal energy from the heat source (e.g., biomass burner, steam boiler) to the drying air, eliminating the need for direct contact between the two fluids. This ensures clean, consistent heating.

Temperature Regulation: Maintaining stable, optimal temperatures (typically 140–180°C) across the dryer. Fluctuations in temperature can lead to uneven moisture removal, causing warping, cracking, or discoloration—common defects that ruin veneer quality.

Energy Efficiency: Maximizing the utilization of input energy. By minimizing heat loss and focusing energy where it’s needed most (on the veneer), heat exchangers reduce operational costs and environmental impact.

Uniform Drying: Partnering with the dryer’s hot-air circulation system to distribute warm, moisture-laden air evenly across every veneer sheet. This prevents “cold spots” or overheated areas, ensuring uniform moisture content and flat, defect-free surfaces.

Why Heat Exchanger Quality Matters for Veneer Drying

Veneers are delicate—too much heat, and they crack; too little, and drying drags on, wasting time and energy. A subpar heat exchanger risks:

Uneven Moisture Levels: Leading to warping or delamination in multi-layer wood products.

Energy Waste: Higher fuel or electricity costs due to inefficient heat transfer.

Poor Surface Quality: Cracking, discoloration, or rough edges that fail to meet premium market standards.

For manufacturers drying birch, oak, rubberwood, or other hardwoods, a high-performance heat exchanger isn’t optional—it’s foundational to producing veneers that meet the strict demands of furniture, flooring, and decorative industries.

Shine’s Heat Exchanger Innovation: Precision, Adaptability, and Sustainability

At Shine Machinery, we understand that one size doesn’t fit all. That’s why our heat exchanger for veneer dryer is engineered to adapt to diverse production needs, with a focus on three key strengths:

1. Multi-Source Compatibility: Our heat exchangers support multiple energy sources, including:

Biomass Burners (Shine’s Patent Technology) : Designed to burn waste wood chips (a byproduct of rotary cutting), this eco-friendly option reduces fuel costs by up to 40% while minimizing carbon emissions.

Thermal Oil/Steam: Ideal for integration with existing plywood production lines, ensuring seamless compatibility with legacy systems.

Hot Water Boilers: A cost-effective choice for smaller-scale operations, balancing efficiency with affordability.

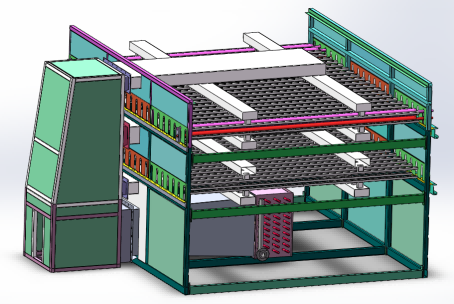

2. Zoned Heating for Uniformity: Shine’s heat exchangers feature zoned designs, with specialized materials and configurations tailored to different sections of the dryer. For example:

Zones near the biomass burner (highest heat) use high-temperature alloys to withstand extreme conditions.

Cooler zones use corrosion-resistant materials to maintain efficiency over time.

This zoning ensures consistent heat distribution, even across large or multi-layer drying chambers.

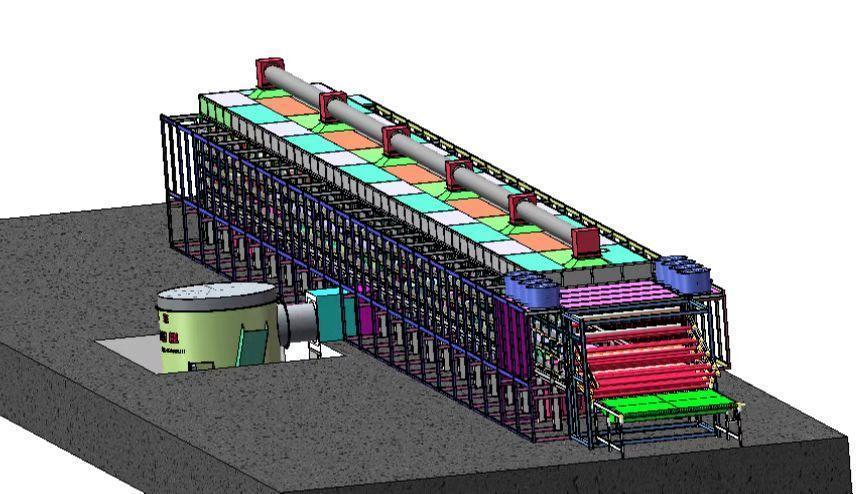

3. Synergy with Hot-Air Circulation Systems: Our heat exchangers work hand-in-hand with Shine’s proprietary hot-air circulation technology. By directing warm, moisture-extracted air back into the drying chamber, we eliminate waste and ensure every veneer sheet—whether thick or thin—receives the exact heat it needs. This synergy is why clients report uniform drying results and up to 240m³ daily output with our 4-layer roller veneer dryers.

Real-World Impact: Why Clients Choose Shine’s Heat Exchangers

For manufacturers worldwide—from European furniture makers to African plywood mills—Shine’s heat exchangers have delivered measurable results:

Reduced Energy Costs: A Brazilian client saved 30% annually by switching to our biomass-powered heat exchanger, thanks to efficient waste wood utilization.

Zero Defects: A Japanese high-end furniture brand reported zero edge cracking or warping after upgrading to Shine’s precision heat exchanger, boosting their product premium.

Faster Throughput: An Indian plywood mill increased daily output by 25% after installing our zoned heat exchanger, matching drying speed to their production line demands.

In the competitive world of wood veneer production, the heat exchanger for veneer dryer is more than a component—it’s the key to unlocking efficiency, quality, and sustainability. At Shine Machinery, we don’t just build heat exchangers; we engineer solutions that adapt to your needs, reduce your costs, and elevate your product.

Ready to transform your veneer drying process? Contact Shine Machinery today to learn how our premium heat exchanger for veneer dryer can help you achieve consistent, high-quality results—backed by decades of expertise and innovation.

Shine Machinery: Precision Heat Transfer, Flawless Veneer Quality.