New Veneer Roller Dryer

Shine Machinery specializes in manufacturing advanced Core Veneer Dryers and Veneer Roller Dryer systems, engineered to revolutionize your veneer drying process. Our Veneer Roller Dryer is a versatile solution designed for efficiently drying top/bottom veneers as well as thickened core veneers, combining space-saving compactness with exceptional throughput capacity.

Product Description of New Veneer Roller Dryer

New Veneer Roller Dryer can dry 0.5-5mm veneer and plywood. The veneer, after drying in the Shine wood veneer dryer, is smooth and the moisture content is uniform, and the surface is in good condition for gluing. Veneer roller dryer with high heat efficiency, and the heat loss is small. The main merit of the veneer drying machine is that it reduces cost. Biomass veneer roller dryer is our patent, which can burn waste wood directly to reduce fuel cost to the most. Face veneer dryer saves energy and is environmentally friendly. Veneer dryer line is no-smoke, low-emission, and high-output.

2-deck veneer roller dryer

Main Features and Advantages of New Veneer Roller Dryer

1. The veneer, after drying by the Shine veneer roller dryer, is smooth, and the moisture content is uniform. The high-temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss. The selling price for veneer dried by roller veneer dryer is higher than natural drying.

2. The new veneer roller dryer adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve an ideal drying effect.

3 . Shine core veneer dryer or face veneer dryer covers a small area, has less ancillary equipment, is convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5 . Each section has with heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark, which can greatly reduce the fuel cost for the user.

Product Parameters of New Veneer Roller Dryer

| Model No | GTH30-32 |

| Working Width | 3m |

| Deck | 2 |

| Heating area length | 28m |

| Cooling area length | 4m |

| Veneer thickness | 0.6-8mm |

| Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is an automatic temperature control and speed regulation system, which can guarantee that the moisture content is consistent. |

| Drying capacity (m³/day) | 40-45cbm |

| Veneer transport speed | 5-22m/min,16A chain |

| Hot air blower | Power:11KW(7pc) |

| Traction motor | Power: 7.5KW,frequency control(2pc) |

| Cold air blower | Power: 11KW(1pc) |

| Air intake fan | Power : 7.5KW(2pc) |

| 4-ton biomass burner | Power: 16.5KW |

| Total power | 134.5KW |

| Actual electricity consumption | About 95kwh per hour |

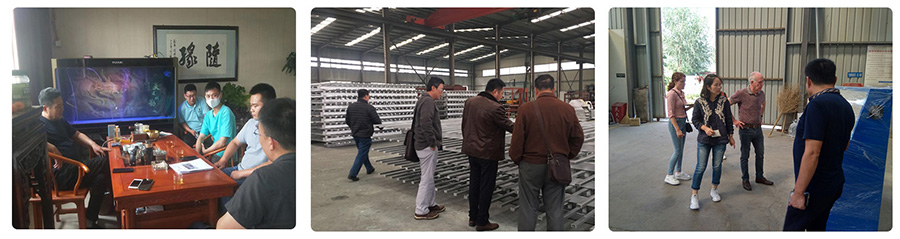

Project Case and Customer Visiting

Thank you for visiting Shine Intelligent's wood veneer dryer production base! We provide professional reception services throughout the entire process for every visiting customer, allowing you to experience quality manufacturing up close.

Our Certificate

As a technology leader in the field of wood veneer drying, Shine Intelligent provides efficient, reliable, and compliant drying solutions to customers worldwide through its independently developed patented technology and strict international standard certification.

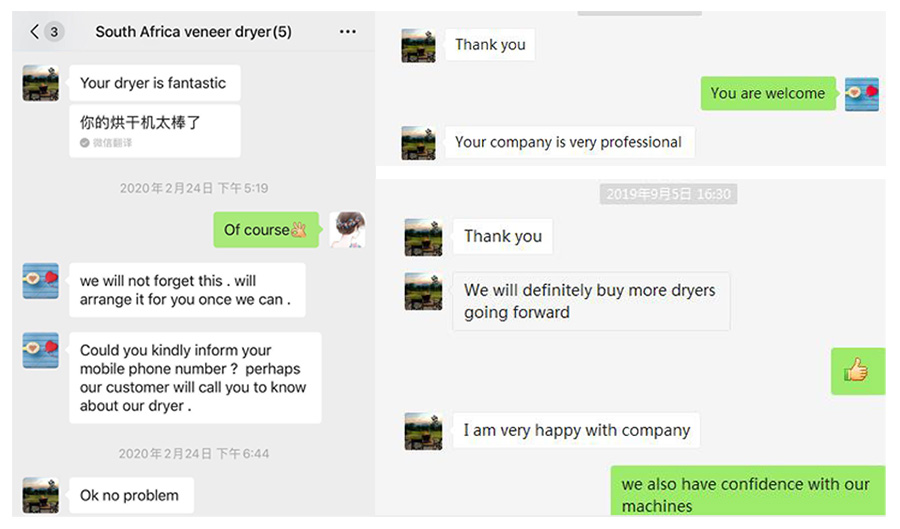

The customer evaluation

✅ 98% repurchase rate - Percentage of repeat purchases by existing customers and referrals of new customers

✅ 4.9/5 rating - Comprehensive rating from third-party customer surveys (2023)

✅ 0 complaints - No after-sales complaints regarding exported equipment in the past three years

Product Packaging

• Each device nameplate comes with a patented QR code that can be scanned to verify the authenticity of the technology.

• Provides patent technology authorization letters for overseas project bidding.

• The R&D team continuously updates the patent pool (adding 3-5 new technology patents each year).