Roller Type Core Veneer Dryer

With over 150 sets of Shine roller veneer dryers successfully operating in Thailand and on-site installations across Vietnam, Myanmar, and Laos, our plywood veneer roller dryer machine has become the preferred choice for smart manufacturers. Designed for maximum efficiency, this innovative dryer features a biomass burner system that directly utilizes local waste wood as fuel, dramatically reducing your fuel procurement costs. Compared to traditional dryers, the Shine plywood veneer roller dryer machine cuts post-operation expenses by 35-40%, delivering a comprehensive drying cost of just $6-12/m³—including labor, fuel, and electricity. Its roller-type design ensures even heat distribution and consistent moisture control, optimizing both energy use and output quality.

Roller Type Core Veneer Dryer

The 2-deck roller-type core veneer dryer is a cost-effective product that uses a new axial flow fan to reduce the overall power of the veneer dryer and save energy. There are models of different lengths and widths to choose from. Whether you are drying eucalyptus, birch, pine, or other wood, you can dry it. The complete after-sales service system can provide 24-hour online service, engineers on-site for installation guidance, remote operation, regular visits to customers, and sufficient spare parts supply, so that you can use it with confidence! If you are looking for a high-efficiency and energy-saving veneer roller dryer, please contact us to provide you with a one-stop veneer service solution.

Product Parameters of Roller Type Core Veneer Dryer

Model No | GTH30-32 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 28m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is an automatic temperature control and speed regulation system, which can guarantee that the moisture content is consistent. |

Drying capacity (m³/24h) | 40-45cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(7pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 7.5KW(2pc) |

4-ton biomass burner | Power: 16.5KW |

Total power | 86.5KW |

Actual electricity consumption | About 61kwh per hour |

Covered Space of the whole machine | 38M X 9M X 3M |

The installation

Extreme cold regions of Russia (-35°C frost protection installation plan)

High humidity environments in Southeast Asia (rust prevention reinforcement treatment)

Sandstorm areas in the Middle East (fully sealed electrical cabinet installation)

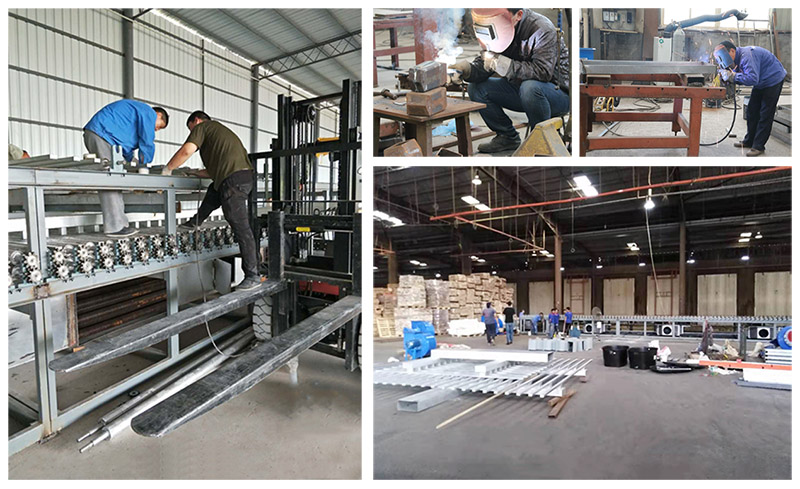

The Factory

Optional waste heat recovery system (energy savings of 25% or more)

Biomass/natural gas/electric heating multi-energy compatible design

Packaging & Shipping

As a professional manufacturer of large-scale wood drying equipment, we deeply understand your concerns about maritime safety. Shine Intelligent provides military-grade maritime protection solutions for each veneer dryer, ensuring that the equipment arrives safely at your factory across the ocean.