Core Veneer Dryers Line

The electricity consumption of the shine veneer dryer has been reduced by 35%, and you are welcomed to conduct an on-site inspection.

Type: Biomass Veneer Dryer

Working Width: 3m(customization available)

Veneer thickness: 0.8-8mm

Heating Area Length: 34m

Drying capacity (m³/day) : 120-130

Heat Source: Biomass Burner (Other heating options available)

24 hours online services(WhatsApp:15806625431)

Core Veneer Dryers Line

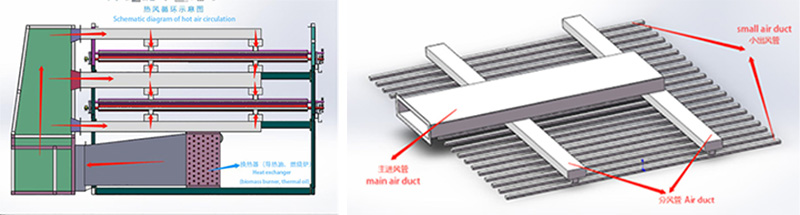

The 4 deck core veneer dryers line adopts a high degree of automation (the degree of automation can be customized as per cutomers specific requirement) to save labor cost and increase the veneer infeeding efficiency. The new axial flow fan reduces the power of the whole machine, which is both energy-saving and efficient. It adopts an advanced heat exchange structure, with high heat exchange efficiency and small heat loss. The veneer dryer can be heated by conventional heat sources such as steam boiler, thermal oil furnace or biomass burner. Shine Machinery provides you with not only the veneer drying products, but also high-quality one-stop service solutions. From factory planning to put into use, Shine can Provide you the professional suggestions.

Product Parameters of Core Veneer Dryers Line

Model No | GTH30-38 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 34m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 120 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 11KW(17pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 287.5KW |

Actual electricity consumption | About 200kwh per hour |

Overall Dimension(L*W*H) | 49m×11m×3.5m |

The well developed heat exchange system, featuring an optimized design and cutting-edge technology, significantly enhances energy utilization efficiency. In the meanwhile the structure effectively minimizes unnecessary energy loss. Its innovative heat exchanging structure and superior performance have been officially recognized and granted the National Invention Patent. It plays an important role in the energy efficiency and power saving of the whole four deck veneer dryers.

Customer Cases

The footprint of Shine's dryer has spread to more than 20 countries around the world, leaving successful customer case sites in multiple regions such as Europe, Southeast Asia, and North America. These widely distributed cases are not only a strong proof of the quality of our equipment, but also provide valuable opportunities for interested customers to have a close understanding of the equipment.

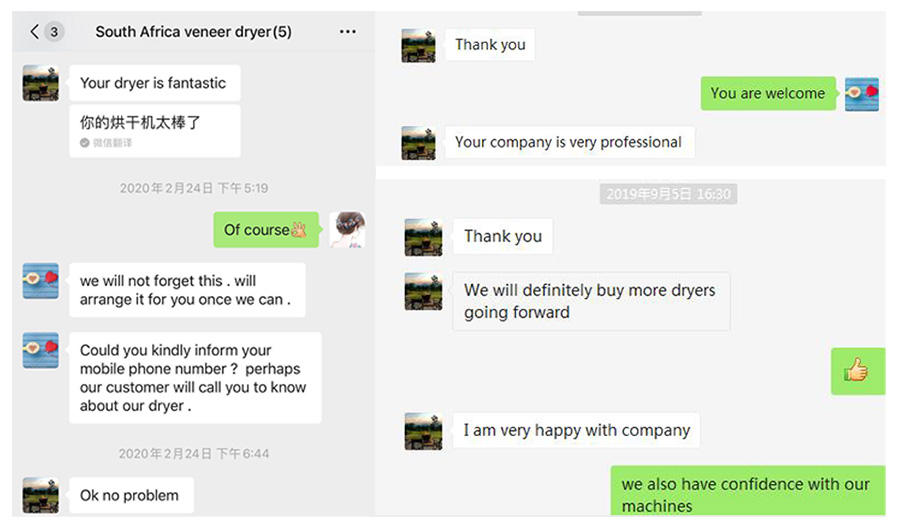

Customer Feedback

Our drying machines have been widely installed around the world, earning numorous praises from clients from every part of the world. We set up a wechat group to invite the workers who are in charge of the veneer dryer and the routain maintenance. In this way, we can monitor the working conditions of the shine veneer dryers. Regular reminder and machine check are part work of our after sales department. Clients frequently commend our equipment for delivering exceptional results, further solidifying our reputation as a trusted leader in industrial drying solutions

The Factory

We have 10 standardized workshops, covering an area of 40000 square meters and has 150 sets of various euipments and has complete machining, heat treatment, punching machines, welding machines, and assembly and painting totaling six production lines.

Our comprehensive after-sales service department consists of fully trained technical support personnel who provide round-the-clock assistance, available 24 hours daily through multiple online platforms for immediate troubleshooting and consultation services.

Packaging & Shipping of Veneer Dryers

Each industrial dryer is carefully shock-proof wrapped to ensure safe transit. Critical components are individually packed with protective materials to prevent damage. The veneer drying parts are then loaded into containers according to the optimized space utilization standards, with proper bracing and waterproof sealing. We provide clear labeling (equipment details, weight, handling instructions) and full shipping documentations (packing list, commercial invoice, manuals). Shipments are tracked until delivery, with optional insurance for added security.