Efficient Veneer Drying Machine

As a leading manufacturer of Veneer Drying Machines and Veneer Wood Making Machines, we offer fully customizable one-stop services to meet your specific production needs. Our Veneer Continuous Dryer is manufactured in a professional factory with precision engineering, ensuring durability and efficiency in every unit.

Shine roller veneer dryer has the advantages of simple operation, safety and practicality, stable operation, and easy maintenance. The processes of hot pressing-leveling-drying are finished at the same time. The veneer after drying is flat, smooth, and without marks, and the moisture content is uniform. The roller veneer dryer is a new generation wood veneer drying machine. It adopts the latest international pressure contact veneer drying technology to ensure the veneer is heated evenly. It can be used to dry rubber wood, eucalyptus, birch, teak, all kinds of hardwood and softwood veneer, etc.

Key features of our advanced drying technology include

✅ High-Quality Construction: The rollers utilize φ89mm special shaft tubes that are corrosion-resistant and rust-proof, guaranteeing long-term performance even in demanding environments.

✅ Flexible Heat Sources: With diverse heat source options (biomass, gas, steam, or electric), our dryer adapts seamlessly to your operational requirements.

✅ Exceptional Productivity: Delivering 2-3 times higher output than traditional dryers, our machine maximizes efficiency while reducing energy costs.

✅ Perfect Drying Results: Ensures flat, wrinkle-free veneer after drying, maintaining premium quality for your Veneer Wood Making Machine production line.

Product Parameters of Veneer Drying Machine

Wood species | Veneer drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

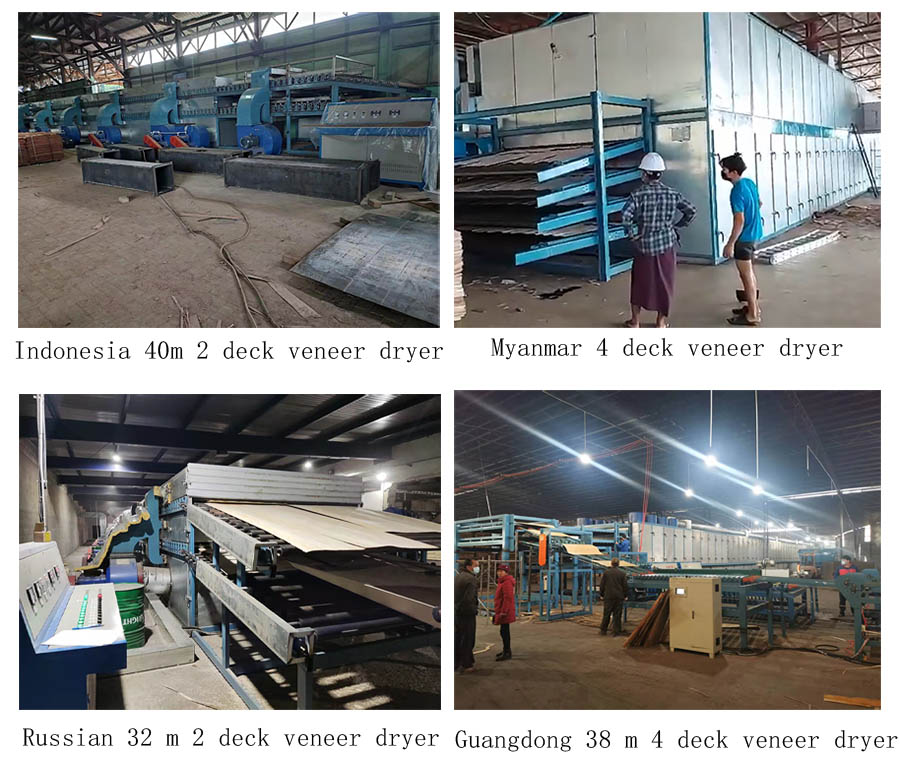

Customer Case

Shine Machinery's wood veneer dryers have been successfully put into production in wood processing plants in more than 30 countries around the world, helping customers achieve efficient, energy-saving, and stable drying operations. Below are some of our selected customer case studies, showcasing the outstanding performance of Shine Machinery equipment in various application scenarios!

The Factory

Shine Machinery, a national high-tech enterprise in the field of wood veneer drying, has an industry-leading modern production base that integrates R&D, manufacturing, and testing. With 20 years of technical experience and more than 500 global cases, it provides customers with highly reliable wood veneer drying solutions.

Packaging & Shipping

✔ Technical expertise – 20 years of focus on wood veneer drying, with patented technology ensuring performance

✔ Quality commitment – Key components with a lifespan of 15+ years and a failure rate of <0.5%

✔ Global delivery – One-stop solution from design to after-sales support