Veneer Dryer For Hot Sale

As a leading wood veneer dryer manufacturer, we proudly present our veneer dryer for hot sale – the Shine Roller Veneer Dryer, engineered to revolutionize your veneer production with unmatched efficiency and quality.

Simple & Safe Operation

A user-friendly control system requires minimal training

Integrated safety features ensure accident-free production

Fully automated process reduces labor costs

Perfect Drying Results

Delivers flawless, smooth veneer with zero roller marks

Maintains uniform moisture content (8-12% standard)

Preserves natural wood color without discoloration

Product Description of Veneer Dryer

Shine Machinery developed and produced a new type of wood veneer dryer, whose combustion heating system can obtain materials on site. Waste veneer produced by veneer peeling machine or veneer slicer, tree bark by debarker and waste wood can be burned directly. It not only solves the key problem of high fuel cost of veneer drying equipment, but also solves the serious problem of waste accumulation in wood processing plant.

2 Deck Veneer Dryer Machine in Zimbabwe

Wood core veneer dryer is composed of heating area and cooling area. Built-in automatic temperature control and speed regulation system, which can automatically adjust the transmission speed and temperature according to the thickness and moisture content of different veneers to achieve the ideal drying effect. The final moisture content can be precisely controlled. Avoid the phenomenon that a large number of veneers are over-dried or the drying does not meet the process requirements.

2 Deck Veneer Dryer Machine in Congo Customer Factory

Veneer dryer chain, Roller running veneer, Outfeed

Advantages of Veneer Dryer

1. The veneer after drying by Shine veneer dryer is smooth, and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. The selling price for veneer dried by roller veneer dryer is higher than natural drying.

2. The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3. Shine core veneer dryer or face veneer dryer covers a small area, has less ancillary equipment, is convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4. Standardized production models can make different sections or decks according to different capacity requirements, which can meet different customers' requirements.

5. Each section with a heat exchanger, which can make full use of the heat and achieve the best drying effect.

6. The fuel source can be the waste wood after peeling or the tree bark, which can reduce the fuel cost greatly for the user.

Product Parameters of Veneer Dryer

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is an automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 70-80cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 119.5KW |

Actual electricity consumption | About 130kWh per hour |

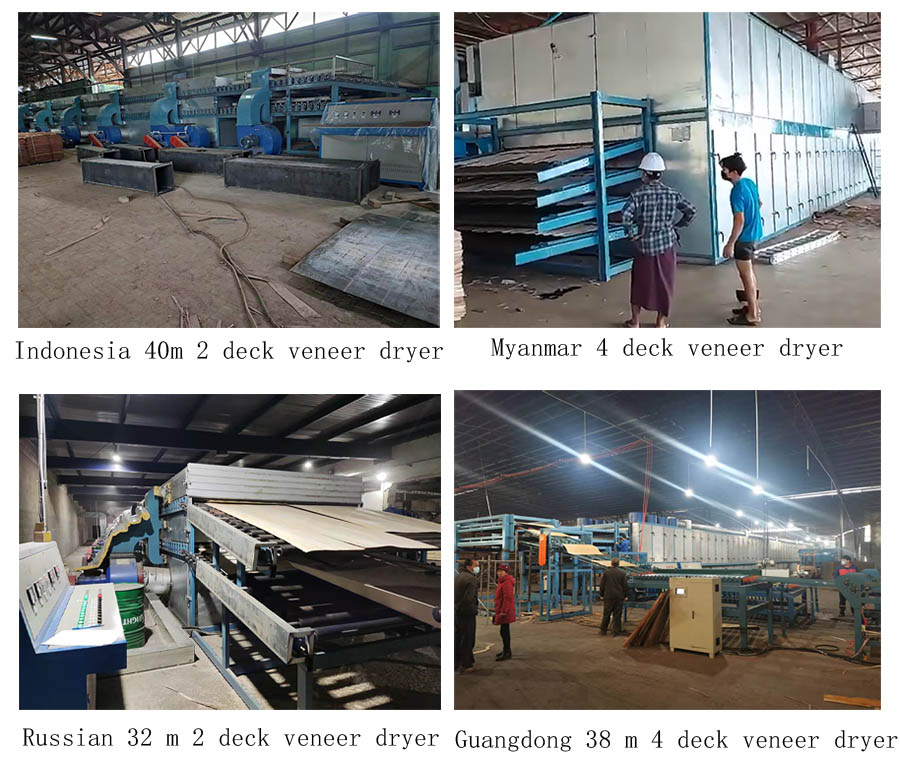

Project Case

At the palm wood processing plant in Indonesia and the rubber wood production site in Myanmar, ShineVeneer Dryer Machine is serving 200+ customers in Southeast Asia with excellent performance!

Our Factory

Our production base not only covers a large area, and has a wealth of supporting measures. Experienced engineers ensure the quality of the machines to the greatest extent possible.

Customer Visiting

Recently, a delegation from Timberland Resources, a famous wood processing enterprise in Malaysia, visited the headquarters of Shine Machinery to inspect the manufacturing process of our Roller Veneer Dryer and highly evaluated the performance of the equipment!

Customers from Malaysia visit

Our Services

Pre-sale services:

1) Provide a free consultation on all Core Veneer Dryer Machines

2) According to the clients' special requirement, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment

3) Train the first-line operator.

After-sales services:

1) 24 hours online service

2) Provide the VIDEO with Install and debugging the equipment

3) Provide technical exchanging

4) Door-to-door service is possible

FAQ

Q: Are you a factory or a trading company?

A: We are a factory that manufactures the machines by ourselves.

Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service, and e-mail service. If you can not deal with the problem, our tech staff will go abroad to service.

Q: What are the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paid against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

Q: Can we visit your factory?

A: Welcome to visit us! Every day we have customers from different countries. By now, we have exported to more than 50 countries.

Other Products

As a professional drying equipment manufacturer, Shine not only provides high-performance Veneer Dryer Machine, but also builds a perfect spare parts supply system to ensure that the equipment operates efficiently for a lifetime!